� �

The New Buick Aluminum Engine

�| by: | J.D. Turlay, E.H. Holtzkemper, and C.G. Studaker |

| Buick Motor Division General Motors Corporation Flint, Michigan |

� re-published by permission in BritishV8 Magazine, Volume XVI Issue 2, October 2008�

�INTRODUCTION

��

The introduction of the new Special for 1961 was the result of a �

re-evaluation of the traditional Buick position in the overall car �

market. With this new concept of a smaller, fine car came the opportunity �

for the Engineering Department to start with a "clean sheet of paper", �

not encumbered with the requirements of utilizing existing tooling or �

components.�

�

It was recognized early that to make the necessary gains in fuel economy �

so important to the customer and yet maintain a level of performance �

acceptable to the discriminating car buyer, weight would be a critical �

factor. The decision to design an engine around major aluminum castings �

was the outgrowth of this realization, due not only to its direct effect �

upon overall car weight, but also it's effect upon the weight of other �

chassis components. By taking advantage of this overall weight reduction, �

engine displacement could be held at a minimum for a given level of �

performance with consequent advantage in both manufacturing and operating �

economies.�

�

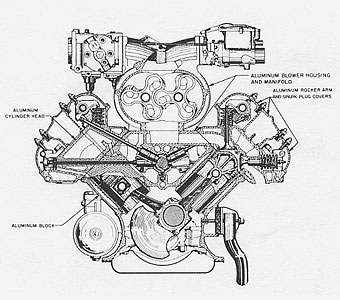

The application of aluminum in engine design is far from new and the �

majority of engines on the market today have utilized this material �

in some form for many years. An aluminum hi-performance V-8 engine was �

designed and built at Buick to power the famous XP-300 and LeSabre �

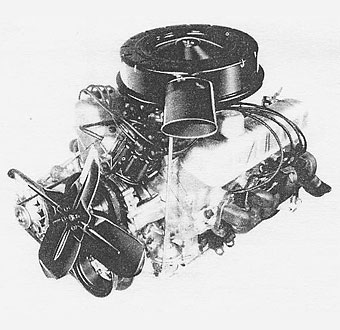

experimental cars of the early 1950's (Figure 1). The new Special engine, �

however, is the first mass produced aluminum V-8 engine to be used in an �

American-built passenger car.�

| �

� |  | �

| Figure 1 EXPERIMENTAL XP-300 ALUMINUM ENGINE | �

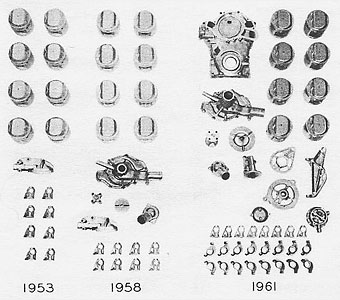

� | Figure 2 EVOLUTION OF ALUMINUM IN BUICK V-8 ENGINE | �

�

Recognizing the advantage of aluminum in making possible both weight and �

cost savings, a gradual evolution has been taking place at Buick since �

the introduction of the present line of cast iron V-8 engines in 1953 �

(Figure 2). Aluminum pistons, rocker arm shaft brackets and oil filter �

base were incorporated in the original design. The water pump cover, �

water manifold, water outlet and timing chain cover were designed for �

die casting in aluminum; however, economic considerations did not permit �

their adoption at that time. All, except the water manifold, have since �

been re-evaluated as aluminum die castings and released for production: �

the water outlet in 1955, the water pump cover in 1957, and the timing �

chain cover in 1958. In addition, the 1961 large Buick engines include �

die cast rocker arms, water pump impeller, generator end frames, generator �

bracket, fan spacer, fuel pump dome and body to further supplement the �

conversion to lightweight aluminum castings. The experience gained through �

the use of the above parts, especially those exposed to the coolant, gave �

us the necessary background to embark on a program of extending the use �

of aluminum to the major castings of the Special engine: namely, the �

cylinder block, cylinder heads and intake manifold. �

�

In addition to the above experience, we have drawn heavily on the �

background of knowledge in the use of aluminum for major engine components �

available from the Power Development Section of the Engineering Staff �

Division, General Motors Technical Center. They have been engaged in �

extensive research and development in this field since 1951 and their �

assistance has been invaluable. Prototype engines for this program�

originated with them, with Buick assisting by serving as prime supplier �

to gain further experience. The production design was started at Buick �

in December of 1958 and much of the experience obtained from the �

prototype program applied directly to the engine being covered by �

this paper.�

�

There has been much discussion regarding the corrosion characteristics �

of aluminum when used in critical locations connected with the engine �

cooling system. Our experience with the water pump cover, timing chain �

cover and water outlet has shown that with proper care in the selection �

of the alloy used, in meeting the design requirements, and in careful �

manufacturing control, corrosion does not become a field problem. All �

of these parts are cast of GM-4097M alloy containing 11.0 to 13.0 �

percent, silicon and less than one percent copper for excellent corrosion �

resistance.�

GENERAL DESCRIPTION

��

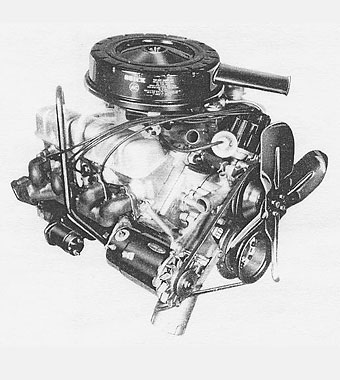

An eight cylinder V-8 engine was chosen to power the new Buick Special due �

to its inherent advantages:

�

1. Small package size.

�

2. Smoothness of operation.

�

3. Rigid construction.

�

4. Excellent output characteristics and

�

5. Light weight.

�

It was felt that no compromise in any of the foregoing could be tolerated �

and still produce a vehicle of the quality desired by our customers. �

�

In view of the projected overall car weight of approximately 2700 pounds, �

a displacement of 215 cubic inches was chosen to provide for excellent �

economy characteristics while giving the driver the nimbleness he has come �

to expect in an American-built automobile. This displacement was obtained �

with a bore of 3.500" and a stroke of 2.800" for a stroke-bore ratio of �

0.8, the same as the original 322 cubic inch Buick V8 engine. �

�

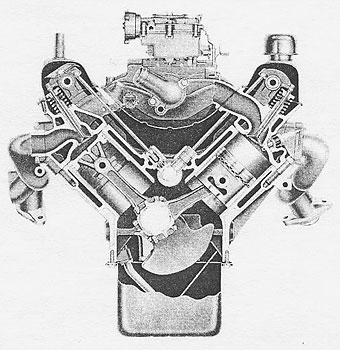

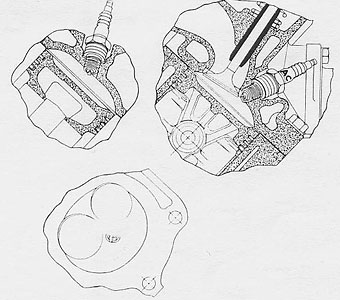

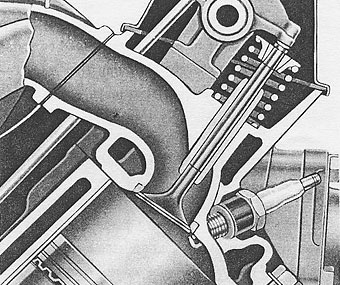

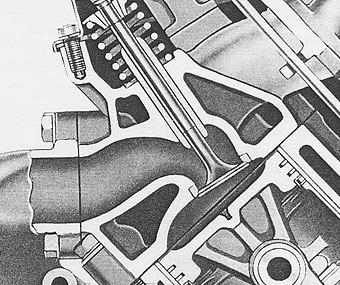

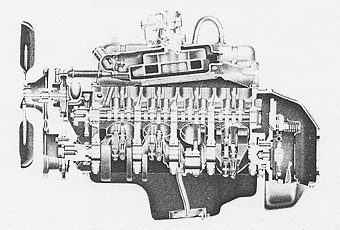

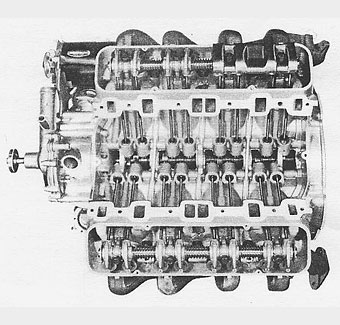

The overall engine compactness is readily apparent from a cross section of �

the engine (Figure 3) which clearly shows the functional use of all available �

space within the engine outline. Exhaust manifolds are neatly tucked in along �

the cylinder banks to reduce the overall engine width. The intake manifold is �

recessed in the "V" of the cylinder heads as close to the curved lifter �

compartment cover as possible to reduce overall engine height.�

| �

� |  | �

| Figure 3 TRANSVERSE CROSS-SECTION OF BUICK ALUMINUM V-8 | �

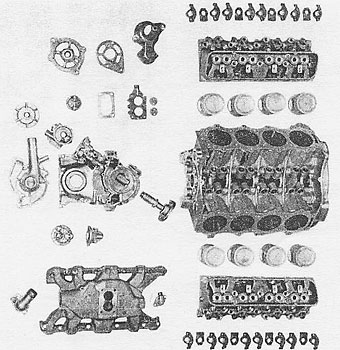

� | Figure 4 ALUMINUM COMPONENTS OF 215 ENGINE | �

�

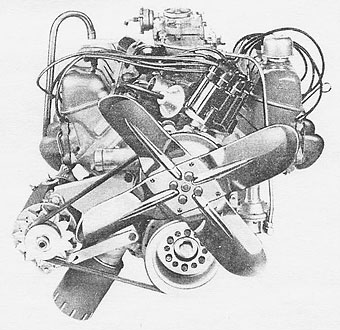

Aluminum castings were utilized wherever possible (Figure 4) in the interest �

of maximizing weight saving. The cylinder block and cylinder heads are made �

by the semi-permanent mold process due to the necessity for sand water jacket �

and port cores. The intake manifold is made as a sand casting. Die castings �

include such components as: timing chain cover, water pump cover, water pump �

impeller, water outlet, flywheel housing, oil pump cover, rocker arms, rocker �

arm shaft brackets, distributor body, starter and generator end frames, �

carburetor throttle body, and oil pressure indicator switch housing. The �

pistons, as in most automotive engines in use today, continue as full permanent �

mold castings.�

�

All other engine components were carefully scrutinized to obtain a design �

providing for minimum weight while maintaining a high level of durability �

and structural rigidity.�

�

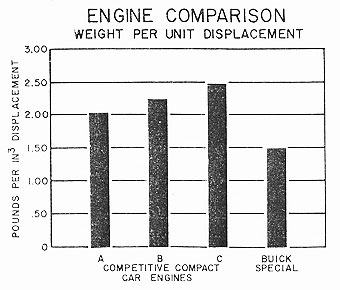

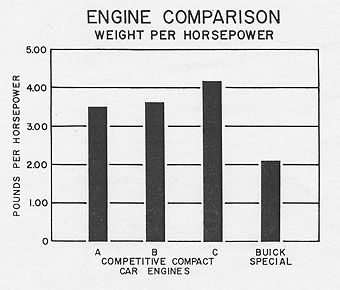

The final result of this weight-conscious approach to the design of the new �

Special engine is a total dry weight of 324 pounds or 1.50 pounds per cubic �

inch displacement (Figure 5). A comparison with several 1960 American-built �

compact car engines reveals that this weight per cubic inch ratio is far �

superior and is the only one with a value under two pounds per cubic inch �

displacement. As an additional measure of the benefits of this concentrated �

attack on the weight problem, a comparison of the performance level in terms �

of pounds per horsepower output reveals a figure of 2.09 for this engine as �

compared to 3.50 for the nearest competitor.�

| �

� |  | �

| Figure 5 COMPARISON OF WEIGHT PER UNIT DISPLACEMENT | �

� | Figure 6 COMPARISON OF WEIGHT PER HORSEPOWER OUTPUT | �

COMBUSTION CHAMBER

��

The American car buyer is becoming increasingly more critical of car �

operating costs and for this reason it was established that the Special �

should operate on regular gas. To accomplish this and still provide maximum �

utilization of the regular grade fuels available, careful attention was �

given the selection of a combustion chamber for the new engine.�

�

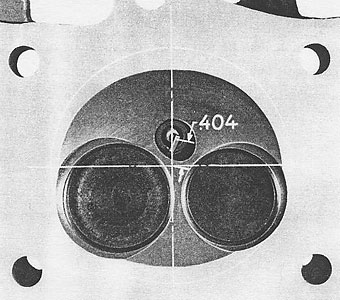

The combustion chamber finally chosen was formed by a slanted, elongated �

saucer shape in the cylinder head accompanied by a shallow circular depression �

in the piston dome (Figure 7). Piston coverage of 15 percent is provided �

by a 0.35" wide land around the top of the piston adding to the turbulence �

of the swirling fuel-air mixture leaving the slightly offset inlet port. �

The spark plug is centrally located, being only 0.404 inches from the �

cylinder centerline (Figure 8) which results in a short, uniform flame �

travel to all parts of the chamber.�

| �

� |  | �

| Figure 7 COMBUSTION CHAMBER | �

� | Figure 8 SPARK PLUG LOCATION | �

� The new design combines the low surface-to-volume ratio advantage of the � hemispherical chamber with the turbulence of the wedge-type chamber for � excellent mechanical octane characteristics. This permits operation with � deposits at a compression ratio of 8.8 to 1 on 92 Research octane fuel � without trace knock. In addition, this chamber includes an in-line valve� arrangement with minimum shrouding of both inlet and exhaust valves � providing a high degree of breathing efficiency.�

�SERVICE

��

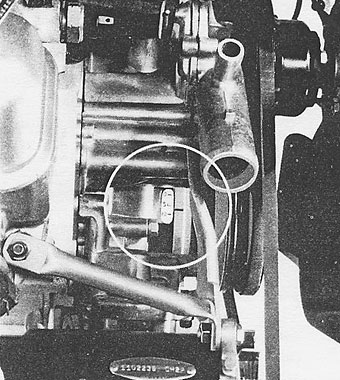

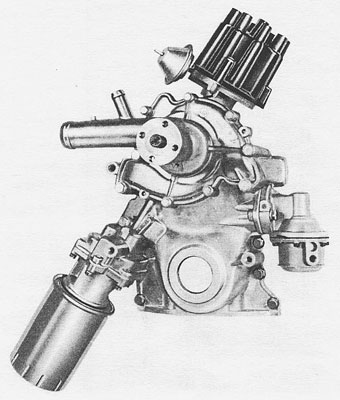

Serviceability was of prime importance in the overall engine arrangement �

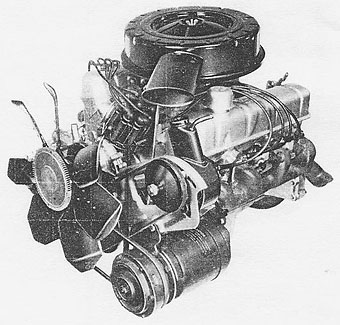

and resulted in several interesting features. The ignition distributor is �

located in the timing chain cover at the front of the engine (Figure 9) �

eliminating the need for the average mechanic to double as a contortionist �

for even a simple point adjustment. The timing indicator, being cast �

integral as a part of the timing chain cover (Figure 10) is conveniently �

located in close proximately to the distributor, permitting the mechanic �

to accurately adjust the distributor and observe the timing point from �

the same position. �

�

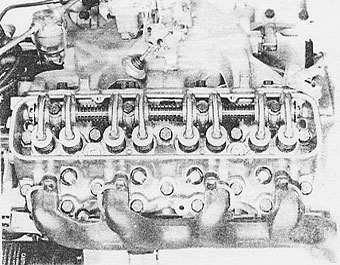

Spark plugs are all easily accessible (Figure 11) even with a full �

complement of accessories - including power steering and air conditioning. �

All cylinder head bolts may be reached with the rocker arm covers removed �

without disturbing the exhaust manifolds, also adding to the convenience �

of the Service Department should head removal ever be required. �

| �

� |  | �

| Figure 9 RIGHT FRONT VIEW OF ENGINE | �

� | Figure 10 IGNITION TIMING INDICATOR | �

| �

� |  | �

| Figure 11 ASSEMBLED CYLINDER HEAD | �

� | Figure 12 ENGINE COOLING SYSTEM | �

COOLING SYSTEM

��

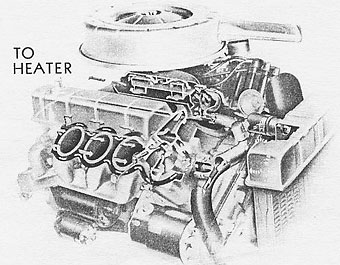

A straight-through type cooling system is employed with the cylinder heads �

being in series with the cylinder block on their respective banks (Figure 12). �

Water enters the pump through a passage in the die cast water pump cover and �

passes through three holes near the hub of the six-vane die cast impeller. �

The rim of the impeller serves as a seal between the inlet and outlet sides �

of the water pump while a cast cavity in the front of the timing chain cover �

forms the rear surface of the pump. This construction permits the die casting �

of both the water pump and the timing chain covers and provides an efficient, �

low-cost water pump. �

�

From the outlet side of the pump, the water divides uniformly and enters the �

cylinder block through openings in front of each cylinder bank. After passing �

around the cylinder walls to the rear of the block, the flow is directed �

through passages in the top deck to the rear of the cylinder heads. From �

here the coolant travels forward through the head to an outlet at the front �

on the intake manifold mounting surface. At this point the water proceeds �

under the manifold proper to the rear and hence to the top of the manifold, �

forward around the carburetor mounting flange to the thermostat housing �

cavity, cast integral with the manifold.�

�

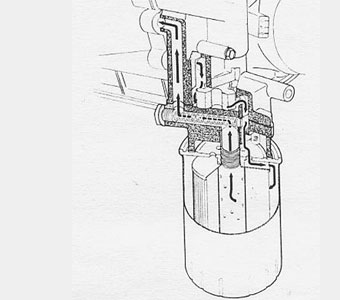

The thermostat by-pass is provided by an integrally-cast tube on the water �

outlet which registers with a hole drilled into the thermostat cavity of the �

intake manifold (Figure 13). A short rubber hose from this tube, in turn, �

connects with a similar inlet on the timing chain cover leading to a passage �

to the inlet side of the water pump. �

�

Water pump and fan speed ratio is 0.85 to 1 to provide adequate coolant flow �

with minimum power requirement and low level of fan noise.�

| �

� |  | �

| Figure 13 THERMOSTAT BY-PASS AND WATER PUMP | �

� | Figure 14 FRONT COVER ASSEMBLY | �

LUBRICATION SYSTEM

��

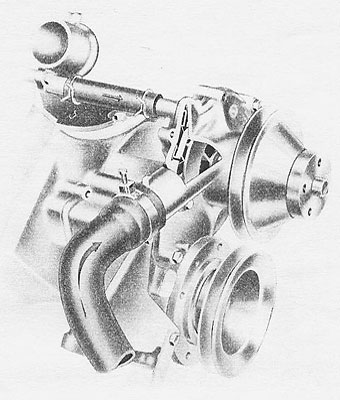

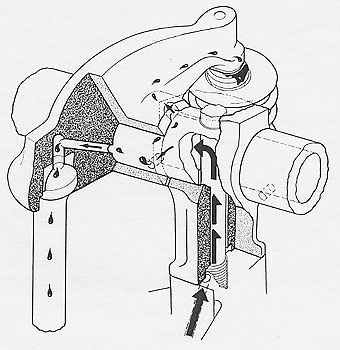

The lubrication system centers around the front mounted oil pump (Figure 14) �

driven directly by the distributor. This necessitates the use of a non-submerged, �

external oil pump remote from the sump located near the center of the oil pan. �

�

The oil pump gear cavity is integral with and machined in the timing chain �

cover insuring correct alignment between the oil pump driving gear shaft and �

the distributor mounting hole (Figure 15). The oil pump cover is a separate �

die casting and serves as a mounting for the full flow, throw-away type oil �

filter cartridge, eliminating the need for a separate oil filter base. Both �

the oil pressure relief valve and the oil filter bypass valve are located in �

the pump cover to further consolidate functional components. A 30 mesh screen �

is located in series with the oil pressure relief valve to prevent stray �

chips and dirt from interfering with the operation of the plunger-type valve. �

| �

� |  | �

| Figure 15 ENGINE OIL PUMP | �

� | Figure 16 ENGINE LUBRICATION | �

�

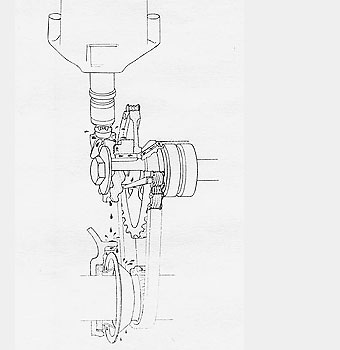

The oil pump intake is provided by a drilled hole down the right side of the �

cylinder block to the center main bearing bulkhead (Figure 16) on which the �

intake screen and housing assembly is mounted. A separate screen assembly, �

of 24 mesh, is located in the housing with a thin annulus of 0.050" thickness �

around the periphery to permit oil to pull over in the event the screen �

becomes plugged. �

�

As the incoming oil leaves the cylinder block it proceeds through passages in �

the timing chain cover to the pump cavity proper. A standpipe effect is �

attained on both the inlet and outlet sides of the pump to insure a sufficient �

reservoir of entrapped oil for reprime of the pump in the event the remainder �

of the system is drained. �

�

High pressure oil passes from the pump outlet into the pump cover, through the �

filter and back into the cover via the steel nipple cast in place for the filter �

mounting. Passages in the pump cover and timing chain cover, in turn, direct the �

oil to the high pressure galleries in the cylinder block. The oil pressure �

indicator light switch is mounted in the oil filter by-pass valve cap since this �

hole serves as part of the outlet passage for the high pressure oil to the block.�

�

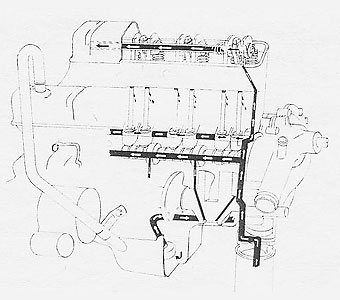

The high pressure oil distribution system consists of two main oil galleries �

drilled the length of the block and intersecting the valve lifter holes for �

approximately one-half the gallery diameter. This then supplies the lifters with �

oil at line pressure and insures an adequate supply of oil to the lifters at all �

times. �

�

Oil is supplied to the main and cam bearings by angled holes drilled from the �

top center of the main bearing bores to the right-hand main oil gallery. Connecting �

rod bearings are furnished oil in the conventional manner with holes drilled �

in the crankshaft.�

�

Full pressure overhead lubrication is supplied by a drilled hole intersecting �

the main oil gallery ahead of the front valve lifter boss on each bank. A cast �

depression in the base of the symmetrical rocker arm shaft bracket provides �

passage for the oil to the mounting bolt hole and thence to the rocker arm shafts �

(Figure 17). By taking the overhead oil from a point ahead of all lifters in the �

main galleries, a maximum amount of entrained air is bled off ahead of the lifters, �

resulting in better lifter performance. �

| �

� |  | �

| Figure 17 OVERHEAD LUBRICATION | �

� | Figure 18 FRONT END LUBRICATION | �

�

Drilled holes are located in the shafts at each rocker arm location and are �

rotated toward the push rod ends of the rocker arms away from the high load point �

to permit a sufficient quantity of oil to escape for proper lubrication of the �

overhead mechanism. Strategically located lubricating grooves are broached in the �

rocker arm bores to provide a film of oil which is distributed by the oscillating �

action of the rocker arm. The push rod seat end of each rocker arm is supplied an �

adequate amount of oil by a hole drilled to the seat end from the rocker arm shaft �

bore. The valve tip end is lubricated by controlled oil flow along the rib section �

on the side of each rocker arm. A slot located in the rocker arm hub allows this�

oil to escape from the chamfer around the inside diameter of the hub and is located �

such that only the required portion of oil finds its way across the top of the arm �

and thence to the valve tip. Excess oil spills off the backside of the rocker arm �

away from the valve tip end. Since this arrangement effectively meters the amount �

of oil reaching the valve stems and guides, no auxiliary seals or shields are �

required.�

�

Oil for lubricating the distributor gears, fuel pump eccentric, timing chain and �

sprockets is supplied in an unusual manner. Leakage oil from the front cam bearing �

is trapped by the thrust flange and delivered through a drilled hole to the sprocket �

and eccentric keyway (Figure 18). A radial slot on the front side of the eccentric �

registers with the keyway and provides an outlet for the oil. In operation, oil is �

thrown radially from this slot to the distributor gear which in turn throws the oil �

onto the timing chain and fuel pump eccentric. This system lubricates all parts �

operating in the front cover without flooding the area, thus reducing the load on �

the front crankshaft seal. �

�

The front crankshaft oil seal is of the graphite impregnated rope type held in place �

in the front cover by a pressed-in steel retainer. A shelf on the inside of the �

timing chain cover reduces the direct flow of runoff oil into the seal area. In �

addition, a slinger mounted on the crankshaft extends over a lip on the seal �

retainer and effectively reduces the amount of oil reaching the seal proper.�

�

The rear main bearing oil seal is also of the graphite impregnated rope type, but �

of necessity, is split with one-half in the cylinder block and the other half in �

the rear main bearing cap. A slinger machined on the crankshaft ahead of the seal �

area operates in a groove machined in the cylinder block. The slinger groove is �

drained by a cast-in slot at the bottom and in addition is vented into the �

crankcase section by a hole drilled near the top. �

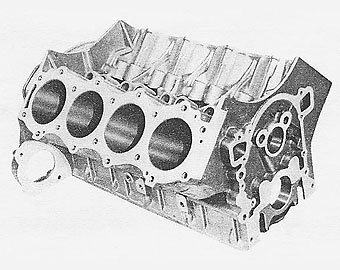

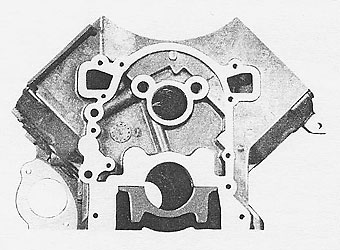

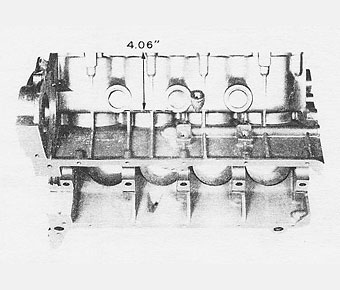

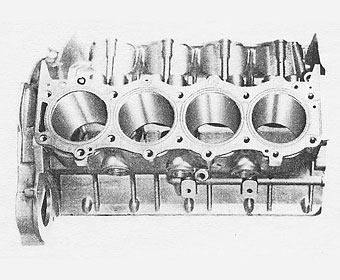

CYLINDER BLOCK

�� The cylinder block, being the largest individual structural component of � the engine, offered the greatest potential weight savings through the use � of aluminum (Figure 19). Semi-permanent mold castings were chosen to permit � use of conventional sand cores in forming the water jackets and lower � crankcase area of the cylinder block. All remaining exterior surfaces of � the casting are formed by metal die sections, resulting in an attractive � casting appearance and providing excellent physical properties for such � critical areas as the cylinder head surfaces.�

� | �

� |  | �

| Figure 19 CYLINDER BLOCK | �

� | Figure 20 CYLINDER SLEEVE AND BLOCK ASSEMBLY | �

�

Long a major deterrent to the widespread use of aluminum cylinder blocks �

in the automotive industry has been the lack of an economical means of �

providing a satisfactory cylinder bore surface. This problem was overcome �

by the adoption of cast-in-place iron sleeves (Figure 20) thus eliminating �

the costly manufacturing complications of wet liners with their inherent �

sealing problems, pressed-in dry sleeves and accompanying increase in expensive �

precision machining requirements. �

�

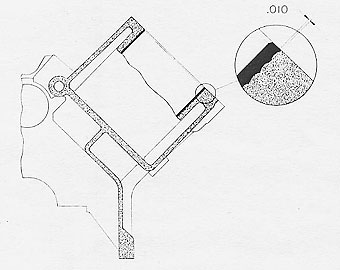

The outside diameter of the centrifugally-cast sleeve is machined with �

circumferential grooves having a pitch of 8 per inch and a depth of 0.010". �

These grooves form a very effective means for mechanically locking the sleeves �

in place. �

�

The cylinder block design incorporates the dropped pan rail (long a Buick engine �

feature) having the oil pan mounting surface 2.250 inches below the crankshaft �

centerline (Figure 21). This configuration provides flat oil pan mounting surface �

and also permits mounting the starter directly in the cylinder block for added �

rigidity. �

| �

� |  | �

| Figure 21 FRONT OF CYLINDER BLOCK | �

� | Figure 22 CYLINDER BLOCK FLYWHEEL HOUSING END | �

�

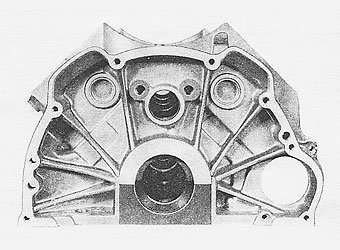

The mounting surface for both the Automatic and Synchromesh transmissions is provided �

by the well-ribbed deep-section flywheel housing end of the cylinder block �

(Figure 22). The effect of this deep block feature is an increase in the natural �

frequency of the engine-transmission assembly in vertical bending which provides �

a smoother, more nearly vibration free installation since this is well above the �

natural frequency response range of the rest of the vehicle. �

�

Two air inlets are provided in the flywheel housing of the cylinder block for the �

Air-Cooled Dual Path transmission. These inlets are covered by the die cast flywheel �

and clutch housings when the Synchromesh transmission is specified. �

�

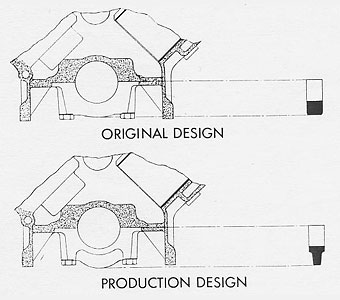

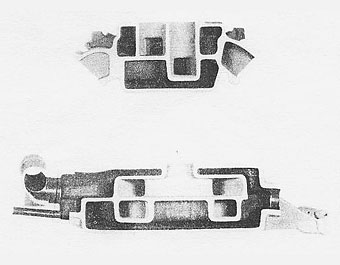

Cast iron main bearing caps are used with the aluminum cylinder block (Figure 23) �

and provide effective control of main bearing clearances throughout the operating �

range. The difference between the coefficient of expansion of aluminum and cast �

iron resulted in a problem in this area during the early stages of the development �

program. With the main bearing caps as originally designed (Figure 24), the higher�

expansion coefficient rate of the aluminum caused the horizontal clearance of the �

bearing to change at a greater rate than the vertical clearance with a change in �

temperature. Subsequent redesign of the main bearing caps, increasing the moment �

of inertia of the cap cross section by 67 percent, resulted in a significant �

reduction in the relative change between the vertical and horizontal bearing �

clearances. �

| �

� |  | �

| Figure 23 BOTTOM VIEW OF CYLINDER BLOCK ASSEMBLY | �

� | Figure 24 MAIN BEARING CAP COMPARISON | �

| �

� |  | �

| Figure 25 BOLT LOADING IN ALUMINUM | �

� | Figure 26 CYLINDER BLOCK WATER JACKET DEPTH | �

�

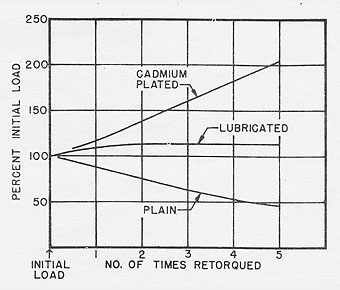

The bolt torque versus clamping load characteristics of aluminum threads presented �

an additional problem in the control of main bearing clearances. Repeated assembly �

of untreated bolts in the aluminum threads resulted in a substantial reduction in �

clamping load for a given bolt torque value (Figure 25). This loss in load caused �

a change in main bearing bore diameter between machining and engine assembly since �

the bearing caps are removed and reinstalled. An investigation into the merits of �

various thread treatments led to the development of a lubricant which gave uniform �

loading on the initial bolt installation as well as on reassembly at the same bolt �

torque. As a result the cylinder head, rocker arm shaft, and main bearing bolts are �

lubricated prior to the initial assembly since all are subjected to high loads and �

require uniform performance. �

�

A minimum thread engagement equivalent to twice the bolt diameter was adopted for �

all bolts threaded into aluminum to permit utilizing the load carrying capacities �

of the respective bolts. There has been no evidence of a loss in bolt loading in �

combination with the aluminum threads even after extensive operation of all types. �

�

The depth of the water jacket in the cylinder block is only 4.06 inches as compared �

to an overall bore length of 5.56 inches (Figure 26). This results in a reduction �

in heat rejected to the cooling water and quicker warm-up while providing adequate �

cooling capacity. Only one cored opening through the cylinder head deck from the �

water jacket is provided at the rear of each bank resulting in a minimum of openings �

for potential cylinder head gasket water leaks (Figure 27). A cylinder head bolt �

pattern featuring five (5) bolts per cylinder was adopted due to the excellent �

performance of this pattern in our larger cast iron V-8 engines. �

�

A 0.015" thick aluminum-coated steel, beaded cylinder head gasket is used and is �

interchangeable between cylinder banks. Double beads are provided around the �

cylinder bores for added protection in these critical areas. �

| �

� |  | �

| Figure 27 CYLINDER BLOCK AND HEAD GASKET | �

� | Figure 28 CYLINDER HEAD WATER JACKET AND PORT CORES | �

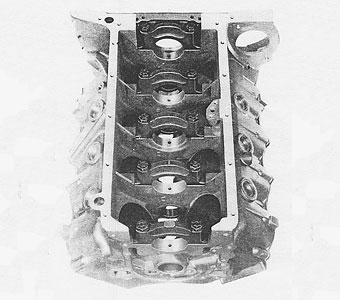

CYLINDER HEAD

��

The cylinder head is also a semi-permanent mold casting having dry sand water �

jacket and port cores. An interesting feature of the cylinder head is the use �

of a one-piece water jacket core (Figure 28) eliminating a pasted core sub-assembly �

and reducing the number of cores required from the core room. This one-piece �

core also results in more accurate control of wall sections and eliminates �

undesirable fins in the water jacket area. Port and water jacket cores may be �

assembled directly into the die eliminating the need for assembly fixtures. �

�

The water jacket core is designed to eliminate a maximum amount of unnecessary �

water while providing excellent cooling for such critical areas as inlet and �

exhaust valve seats, exhaust valve guides and spark plug bosses. The one-piece �

core design results in a triangular section having good structural strength �

characteristics for handling in the foundry.�

�

The elimination of the water jacketing over the inlet ports permits an open �

construction on this side of the cylinder head for a lightweight casting. Over �

head lubricating oil drains freely through this area to the cylinder block.�

| �

� |  | �

| Figure 29 INLET PORT | �

� | Figure 30 EXHAUST PORT | �

�

Both inlet and exhaust ports (Figures 29 & 30) are streamlined to reduce �

to a minimum the resistance to flow of both the incoming fuel-air mixture and �

the departing exhaust gases. The exhaust port is kept short to reduce heat �

rejected to the cooling water and the elimination of the conventional exhaust �

crossover ports further minimizes the cooling requirements. �

�

Valve seat inserts of alloy cast iron are employed and are assembled into the �

cylinder head by a shrink fit process. Both valve and seat insert life have been �

very good, attributable in part to the excellent thermal conductivity of the �

aluminum head and the water jacketing around the valves. Separate, pressed-in-place �

alloy iron valve guides are also used to complete the cylinder head assembly. �

CRANKSHAFT

� �

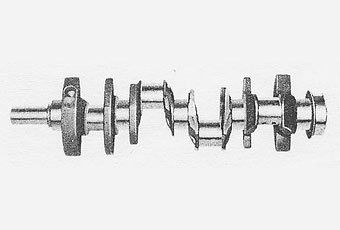

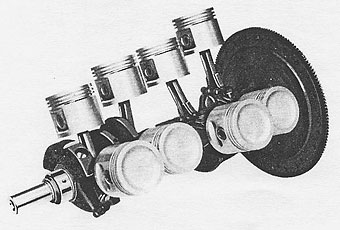

The crankshaft is an Arma-steel casting having the counterweight periphery �

and cheeks cast to size reducing casting weight and machining required �

(Figure 31). �

�

The counterweights are contoured for uniform clearance with the piston skirts, �

thus utilizing the most effective room available for counterweighting (Figure 32). �

In addition, the counterweights are oriented in the most advantageous plane for �

balancing the engine with the minimum amount of material. This design approach �

results in a finished crankshaft weighing only 38.4 pounds. The main bearing �

journal diameters are 2.300" and the crank pin diameter 2.000", which when �

coupled with 1.400" crank throw, results in an overlap of 0.75".�

�

The crankshaft end thrust is taken on a flange bearing at the center main bearing �

bulkhead (Figure 33). All main bearings are of steel-backed babbit material with �

a groove in the upper insert and plain lower inserts. The elimination of a groove �

in the lower insert increases load carrying capacity and also reduces oil pump �

flow requirements by effectively reducing leakage oil at the main bearing and �

partially metering the oil to the connecting rod bearings.�

| �

� |  | �

| Figure 31 CRANKSHAFT | �

� | Figure 32 POWER TRAIN | �

| �

� |  | �

| Figure 33 LONGITUDINAL CROSS-SECTION OF ENGINE | �

� | Figure 34 PISTON AND CONNECTING ROD ASSEMBLY | �

CONNECTING ROD AND PISTON

��

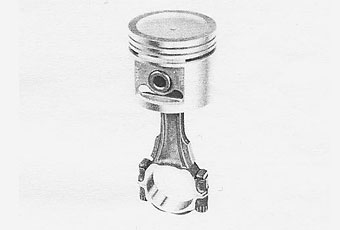

The connecting rods are made of SAE 1141 forged steel and have a center distance �

of 5.660" providing a conservative rod length to stroke ratio of 2.02 (Figure 34). �

Weight control is accurately maintained by the milling of weight bosses located �

at the connecting rod assembly center of gravity. The connecting rod bearings �

are also of steal backed babbit material.�

�

The piston is a one-piece aluminum alloy casting featuring the long-standing �

Buick practice of a full skirt, double trans-slot design. Windows are cast �

beneath the piston pin bosses to effectively divorce the skirt from the bosses �

in this area. Better dimensional control throughout the operating load range is �

obtained with this construction since the lower skirt is not as readily affected �

by pin boss deflections. This piston, coupled with the 0.875" diameter piston �

pin pressed into the connecting rod small end, supplies a rugged structural �

starting point for the transmission of mechanical energy to the flywheel. �

�

Two 5/64" compression rings and one 3/16" steel rail oil ring are provided with �

the top compression ring and the oil control ring chrome plated.�

VALVE TRAIN AND DRIVE

��

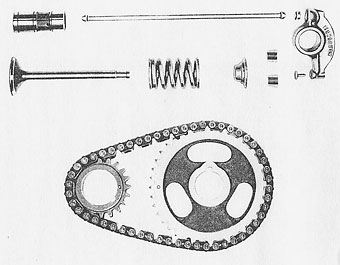

The alloy iron camshaft is driven by a 3/8" pitch chain through a sintered iron �

crankshaft sprocket and a cast iron camshaft sprocket (Figure 35). Hydraulic �

valve lifters are used with both Synchromesh and Automatic transmission engines. �

Push rods are made of 1/4" steel rod, upset and hardened at both ends. �

�

Die cast rocker arms similar to those introduced on the 1960 Buicks are employed �

to further extend the application of light metals to this engine. Inserts are �

installed at each end of the rocker arm with the ball seat for the push rod being �

of sintered iron and the valve-tip pad an upset steel insert. �

�

Inlet valve diameter is 1.500" and the exhaust valve diameter 1.3125". Both �

valve stem diameters are basically 0.340 inches with 0.0005 inches taper in the �

length of the stem - being smaller it the bottom. �

�

Enjoying this article? Our magazine is funded through the generous support of readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

| �

� |  | �

| Figure 35 VALVE TRAIN AND DRIVE | �

� | Figure 36 INLET MANIFOLD SECTIONS | �

INLET MANIFOLD AND CARBURETION

� �

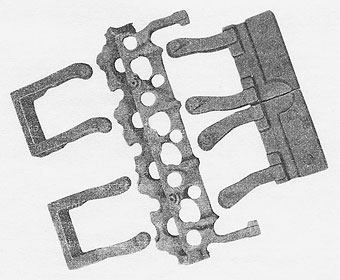

The intake manifold is the only completely sand cast component due to the �

complexity of coring in a V-8 manifold (Figure 36) and to the more flexible �

nature of the sand casting process.�

�

The branch size of the manifold was made as small as possible, consistent �

with good breathing characteristics, to provide a minimum manifold volume �

for instant response under changing load conditions. �

�

The intake manifold heat is provided by the water jacket through which all �

of the engine coolant flows. This results in a rapid rate of warm-up due to �

the excellent thermal conductivity characteristics of the aluminum. Another �

important advantage of this method of supplying manifold heat is the uniformity �

of temperatures of the mixture supplied to the individual cylinders. �

�

A two barrel carburetor is standard equipment on both Synchromesh and Automatic �

transmission engines and incorporates aluminum throttle body which, in �

conjunction with a metal carburetor to manifold gasket, provides excellent �

heat transfer characteristics. This construction reduces appreciably the �

tendency of the throttle valves and idle system to "ice up" under adverse �

atmospheric conditions. �

FUEL SYSTEM

�� The fuel pump is mounted low on the loft side of the front cover (Figure 37) � and driven by a sintered iron eccentric mounted on the camshaft. A glass bowl, � paper cartridge fuel filter is standard on all engines and is mounted near the � carburetor to prevent foreign material from entering the critical needle seat or � jet areas. Metal lines are used between the carburetor and the fuel pump with � metal and rubber lines between the fuel pump and tank.�

� | �

� |  | �

| Figure 37 LEFT FRONT VIEW OF ENGINE | �

� | Figure 38 FRONT VIEW OF ENGINE | �

EXHAUST MANIFOLDS

��

The cast iron exhaust manifolds have passages with gradually increasing �

cross-sectional areas to minimize resistance to flow of the burned gases.�

�

The right manifold incorporates a heat stove, which in conjunction with a �

stainless steel tube running through the manifold proper, supplies heated �

air to actuate the carburetor automatic choke. No heat valve with its potential �

sticking or rattle problem is used since the intake manifold is water-heated.�

�

A ball-type flange is used at the exhaust manifold to pipe junction, eliminating �

the need for a separate gasket and also providing flexibility for proper alignment �

of the exhaust system at this point.�

ELECTRICAL

�� The coil is mounted on the intake manifold forward of the carburetor in close � proximity to the distributor (Figure 38), resulting in a short high-voltage lead � wire for minimum voltage loss. The resistor type spark plug wires are held in place � with plastic clips attached to a bracket on each rocker arm cover. Extended reach � AC 45FFS spark plugs are used with a thread length of 1/2".�

�ENGINE VENTILATION

�� Engine ventilation inlet air is provided by a combination breather and filter cap � in the left rocker arm cover. The outlet for crankcase gases is provided by a � ventilator pipe in the right rocker arm cover, which extends down into an area � below the pan rail near the fore and aft centerline of the engine. A baffle is � mounted on two rocker arm shaft brackets beneath the outlet pipe (Figure 39) � preventing oil from splashing out the breather pipe and also providing a relatively � low velocity area for entrained oil to separate from the departing crankcase gases.�

� | �

� |  | �

| Figure 39 TOP VIEW OF ENGINE WITH COVERS REMOVED | �

� | Figure 40 ACCESSORY MOUNTINGS | �

ENGINE COVERS

� �

Valve rocker arm covers are of stamped steel, zinc plated for rust resistance and �

to further accentuate the appearance of the unpainted aluminum components. Right �

and left cover stampings are basically the same with the assemblies modified to �

take the ventilator breather cap in the left cover and the ventilator pipe in the �

right cover. �

�

The lifter compartment cover is formed by the intake manifold gasket extending �

across under the manifold proper and lengthwise to vertical walls at the front �

and rear of the cylinder block. Rubber seals are installed between the gasket �

and cylinder block at the end walls with a hardened steel clamp installed over �

the gasket. The clamp arc is designed to provide a uniform load on the gasket �

when torqued to the specified limits. �

OIL PAN

�� The oil pan is also a zinc plated steel stamping with the major sump area located � near the fore-and-aft centerline of the engine as dictated by chassis installation � requirements. �

�ACCESSORY MOUNTINGS

� �

The accessory mountings with a new engine design are usually left until �

all other components have been completely laid out. Consequently, the engine �

designer is concentrating on basic engine problems while the chassis and �

sheet metal designers are busy at work laying claim to all available space �

surrounding the engine. The end result is a frantic scramble to find �

suitable locations for mounting the generator, power steering pump, air �

conditioning compressor, etc. However, with engine compartment room at a �

premium in this installation, close cooperation between all design sections �

involved resulted in the maximum utilization of the space available.�

�

The generator is mounted low on the right-hand side of the engine directly �

in the fan blast for improved cooling. The rear end frame is attached �

directly to a boss on the exhaust manifold and the front supported by a �

simple triangular stamping bolted to the rear cover. An additional tubular �

brace is provided between the front pivot point and an end cylinder head �

bolt for increased mounting stiffness. A three-point drive is used with a �

single belt driving the generator and water pump.�

�

The power steering pump is mounted in front of the left cylinder head �

(Figure 40) with the rear bracket bolted to bosses provided on the head �

and the front bracket attached to the timing chain cover. �

�

The air conditioning compressor is mounted low on the left side of the �

engine with the rear mounting attached directly to the cylinder block. �

The front mounting bracket is shared with the power steering pump on �

those cars equipped with both, or is a similar but simplified bracket on �

non-power steering air conditioned cars. �

�

Both the power steering pump and air conditioning compressor are driven �

by a two-point drive with the belts going directly from the crankshaft �

pulleys to the individual accessory pulleys. Each accessory is adjustable �

to provide for belt tightening. �

�

These accessory mountings, being attached directly to the basic engine �

wherever possible, result in a rigid, vibration-free assembly so essential �

with the reduced mass of the aluminum engine. �

TEST RESULTS

��

During this development program experimental and initial production engines �

underwent over 10,000 hours of various dynamometer testing and 1,000,000 miles �

of operation in test cars prior to actual announcement to the public. No major �

engine failures occurred throughout this extensive development program attesting �

to the durability of this sturdy, yet lightweight engine.�

�

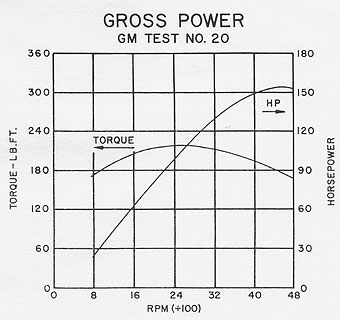

The adequate valve sizes in conjunction with the streamlined ports and manifolds �

result in an engine output curve giving excellent mid-range torque while �

maintaining a high level of horsepower output at speeds above 4000 R.P.M. �

(Figure 41). On a gross output basis, the engine is rated at 220 lb.-ft. �

torque at 2400 R.P.M. and 155 horsepower at 4600 R.P.M.�

�

�

Figure 41�

�

ENGINE OUTPUT - GM TEST NO. 20�

OPTIONAL ENGINES

�� An optional engine including a four barrel carburetor and a compression ratio � of 10.25 to 1 is available for those applications requiring an even higher � level of performance. This option increases the maximum torque output of the � engine to 230 lb.-ft. at 2800 R.P.M. and the horsepower to 185 at 4800 R.P.M., � also on a gross output basis. �

�CONCLUSIONS

� �

As a result of the experience gained during this development program as well as �

production experience to date, we feel the following conclusions to be important.�

�

1. A pronounced weight savings has been made through the extensive use of aluminum �

in this engine with no loss in engine output or durability.�

�

2. The basic goals of a quiet, durable, yet responsive engine have been attained �

by careful design consideration when combining the light weight of aluminum with �

the structural and wear characteristics of cast iron in critical areas.�

�

3. Normal care of the cooling system has been found to be entirely adequate in �

the control of corrosion in this aluminum engine. �

�

4. Engineering problems connected with an aluminum passenger car engine have been �

satisfactorily overcome and the further extension of aluminum to future engines �

will be governed primarily by economic considerations. �

APPENDIX

�GENERAL SPECIFICATIONS

�| Bore, In. | 3.50 | |

| Stroke, In. | 2.80 | |

| Displacement, Cu.In. | 215 | |

| Numbering System, Front to Rear | ||

| Left Bank | 1-3-5-7 | |

| Right Bank | 2-4-6-8 | |

| Firing Order | 1-8-4-3-6-5-7-2 | |

| Compression Ratio | 8.8-1 | |

| Crankshaft Main Bearing Diameter, In. | 2.300 | |

| Crankpin Journal Diameter, In. | 2.000 | |

| Connecting Rod Length, Center to Center, In. | 5.66 | |

| Rocker Arm Ratio | 1.6-1 | |

| Type of Lifters | Hydraulic | |

| Valve Spring Load, Lb. | ||

| Valve Closed | 64 | |

| Valve Open | 164 | |

| Valve Lift, In. | ||

| Inlet | 0.383 | |

| Exhaust | 0.383 | |

| Valve Head Diameter, In. | ||

| Inlet | 1.500 | |

| Exhaust | 1.3125 | |

| Valve Timing | ||

| Inlet Opens. Deg. BTC | 29 | |

| Inlet Closes, Deg. ABC | 71 | |

| Exhaust Opens, Deg. BBC | 67 | |

| Exhaust Closes, Deg. ATC | 33 | |

| Timing Point | Valve 0.004 In. Off Seat | |

| Engine Oil Pressure, Maximum P.S.I. | 33 | |

| Crankcase Oil Capacity, Qt. | 4 | |