Larry Nicholas' '64 MGB V8, part 2

as published in British V8 Newsletter, Volume XII Issue 3, September 2004by: Greg Myer

Since I told you the hard part of making the Ford fit in the early MGB, I'm going to drop back and fill you in on the engine itself. As I noted, it's out of a pickup. Larry wants reliability: a motor that always lights right up and idles smoothly. It should sound good too. He wanted ease of operation too, just in case of an emergency where his wife Cheri needed to drive it (she already foresees many of these occasions arising). With the light weight of the B, any Ford V8 will create a high performance atmosphere.

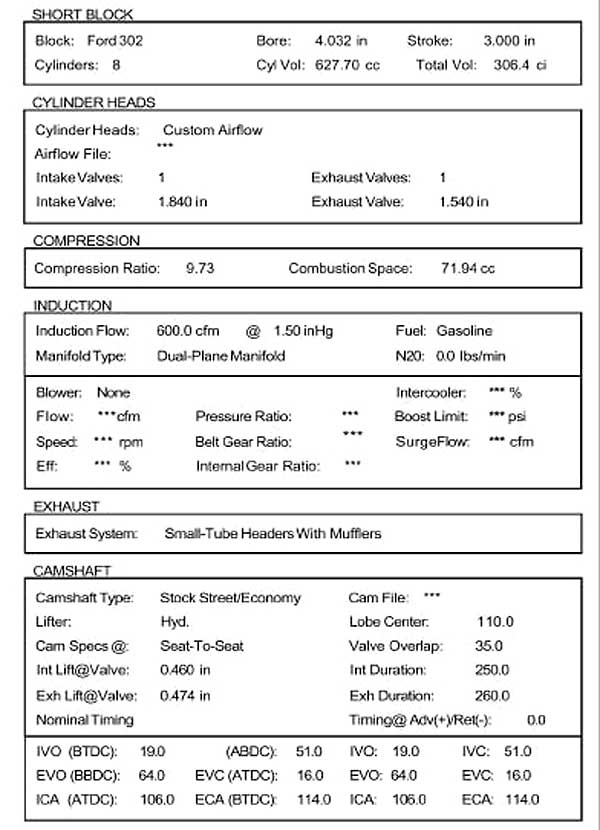

With all of this in mind, I sat down at the computer, armed with a Comp Cams catalog.

Why the computer? Because I have the Dyno 200 Simulation program in it. There is a

lot of information needed to get good results, but a little time is well spent here.

Some of the information you need to enter is: manufacturer, engine type, bore size,

stroke, valve size, ported or stock (street ported or race), V8 combustion chamber

cc's and compression, CFM of the carburetor, intake manifold type, exhaust type-manifold

or headers (large or small tube), open or muffled, and all the cam specs you can imagine,

and some you can't (that's what the catalog is for). There's more if you want to get

technical. How good is this program? I can't say for sure. As we all know, a pro

engine builder can build 2 engines as identical as humanly possible, and have a 10,

15, or 20 H.P. difference. So whatever the computer says isn't the final word. But...

and it's a big but, by dialing in different specs on the basic setup, you can get a

rather good idea of the H.P. or torque output of various cams, or carburetors, etc.

It will also let you know where in the RPM range that power will be. That's important!

With Larry's car we knew going in that we were going to use a Dana 44 with 3.07 gears,

and a C-4 automatic, with a stock-like torque converter.

The engine will most likely never see the high side of 4500 RPM, and even that's wishful

thinking. So, I typed in specs for several cams and came up with an XTREME ENERGY

hydraulic cam which is a dual pattern design. Dual pattern meaning the intake and

exhaust events are different. In this case, the exhaust valve opens farther and remains

open for a long period of time, or degrees. That's important for the small block Ford.

At least one with factory cast heads. The exhaust ports are more constricted than the

intakes, making a tighter turn to exit.

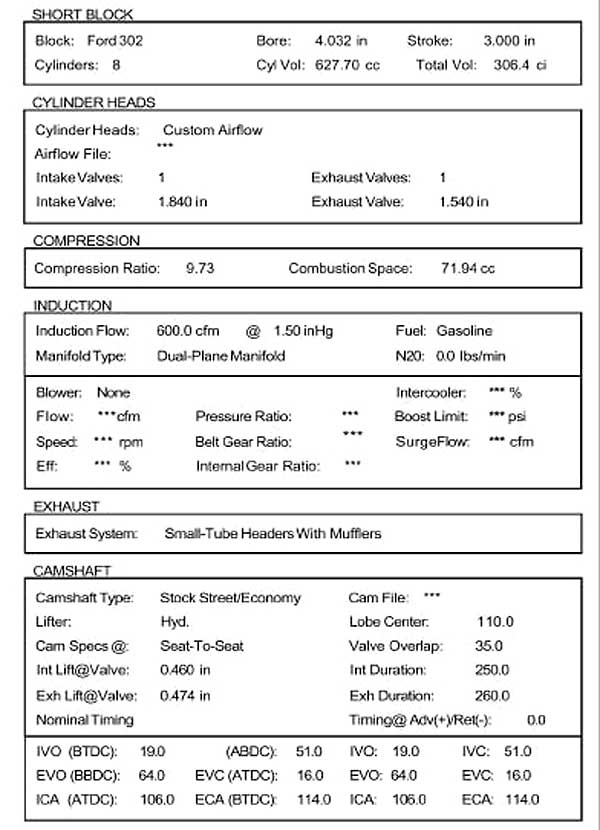

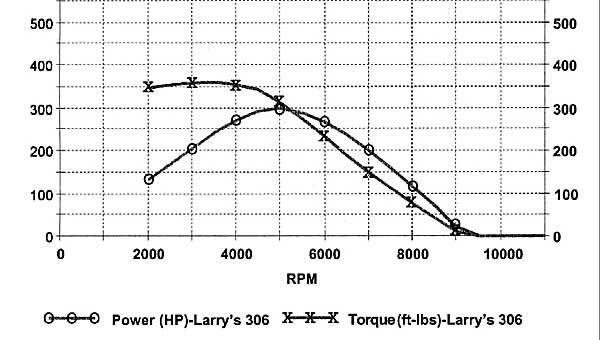

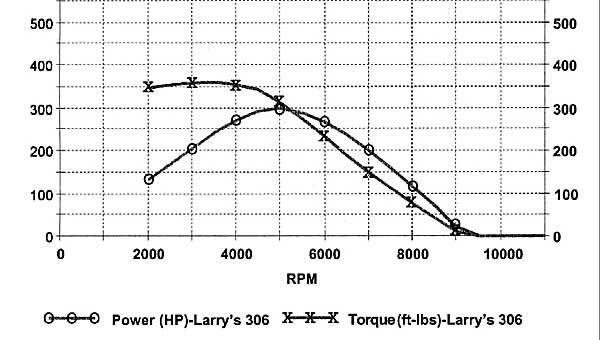

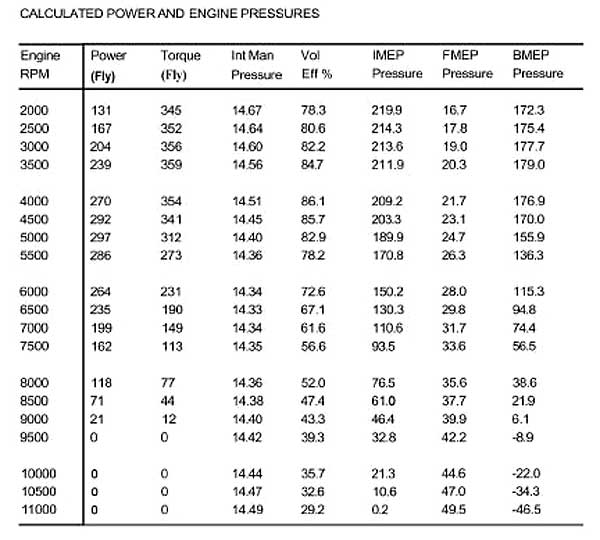

What I wanted was a fat torque curve in the lower RPM's. This will work well on the street with the higher gears and automatic. As the graph and charts show, the torque is almost 350 at 2000 RPM and stays up there throughout the usable RPM range.

This will result in a good swift kick in the bucket seat when you punch the throttle. This along with easy cruising and decent gas mileage should make a nice combination.

I had an old Edelbrock F4B intake manifold. Larry liked that because it was the one Shelby used on the Sunbeam Tiger when the engines were equipped with 4 barrel carburetors. It's too high for the hood and a scoop had to be added, but more on that at a later date. As built, the motor will be slightly different than the computer printouts. I believe the compression will be slightly lower, and Larry got a deal on a Carter carburetor from one of his buddies at work. It has a higher CFM rating than we used here. Still, I think we have a reasonable view of what the results will be.

|

Enjoying this article? Our magazine is funded through the generous support of readers like you! To contribute to our operating budget, please click here and follow the instructions. (Suggested contribution is twenty bucks per year. Feel free to give more!) |

What I wanted was a fat torque curve in the lower RPM's. This will work well on the street with the higher gears and automatic. As the graph and charts show, the torque is almost 350 at 2000 RPM and stays up there throughout the usable RPM range.

This will result in a good swift kick in the bucket seat when you punch the throttle. This along with easy cruising and decent gas mileage should make a nice combination.

I had an old Edelbrock F4B intake manifold. Larry liked that because it was the one Shelby used on the Sunbeam Tiger when the engines were equipped with 4 barrel carburetors. It's too high for the hood and a scoop had to be added, but more on that at a later date. As built, the motor will be slightly different than the computer printouts. I believe the compression will be slightly lower, and Larry got a deal on a Carter carburetor from one of his buddies at work. It has a higher CFM rating than we used here. Still, I think we have a reasonable view of what the results will be.

A good way to check this is by going to the nearest drag strip. There you can have

the car weighed and run it. Once it's dialed in, your MPH can be used in a math

equation to determine exactly what HP is getting to the pavement.

I enjoy playing with... (ahem)... using this program in a scientific manner. (And it sure beats playing solitaire or any other game in the computer.) Jeg's sells this program for about $40.00 and I think it's money well invested.

Steve, a Triumph type friend, has a TR4. During a rebuild he brought me the head to port, along with Triumph factory instructions. When I finished, I cc'd the chambers and used all the information to feed this program. My HP and Torque graphs were close to those supplied by the factory. Not exact, but very close. The engine is now in the car and close to being fired up. Larry is itching for the running. He'll be here this weekend to finish the wiring and we'll see what happens.

Disclaimer: This page was researched and written by Greg Myer. Views expressed are those of the author, and are provided without warrantee or guarantee. Apply at your own risk.

I enjoy playing with... (ahem)... using this program in a scientific manner. (And it sure beats playing solitaire or any other game in the computer.) Jeg's sells this program for about $40.00 and I think it's money well invested.

Steve, a Triumph type friend, has a TR4. During a rebuild he brought me the head to port, along with Triumph factory instructions. When I finished, I cc'd the chambers and used all the information to feed this program. My HP and Torque graphs were close to those supplied by the factory. Not exact, but very close. The engine is now in the car and close to being fired up. Larry is itching for the running. He'll be here this weekend to finish the wiring and we'll see what happens.

Disclaimer: This page was researched and written by Greg Myer. Views expressed are those of the author, and are provided without warrantee or guarantee. Apply at your own risk.