The cumbersome MGC was a flop but the MGB V8 couldn't fail with its lightweight

Rover engine. So why were so few made? Why is it not made now? Chris Harvey

looks at the fate of MG's cut-price supercar that is now valued as an appreciating

asset as well as an appealing road burner.

as published in British V8 Newsletter, Volume XV Issue 3, December 2007

Re-printed unedited by exclusive written permission of "Classic and Sportscar".

(This article originally appeared in the June 1979 issue of "Old Motor" magazine.

Sometime between 1979 and 1983, Old Motor magazine was re-launched as Classic and Sportscar.)

You know what they say about MGs: they are the most popular, loveable sports cars in the world, but they don't go fast enough. You can just about top the ton in the current antique, the MGB, if you live on the right side of the pond; if you are unfortunate enough to be an American enthusiast, you'll be lucky to squeeze 90 out of your emission-strangled B. Why are they so popular, then? Because they are the last rip-roaring hair-in-the-air, well-nigh indestructible sports car in full-scale production. The B might ride like the rocky road to Dublin but it will cling on when most of the rest have slid into oblivion. All it needs is a bit of oomph, so it is amazing that Abingdon's attempts at producing a really quick car have met with commercial disaster. Both the MGC (MGB plus two cylinders) and the MGB GT V8 (MGB plus four) were good for more than 120mph, but the C handled like a barge because the engine was too heavy and the V8 was killed by politics and the totally false impression that it gobbled fuel in the height of an energy crisis. In fact they made only 2591 V8s; with the exception of the Boy's Own Paper hot rod, the MGA Twin Cam (of which 2111 were built) it was the smallest production run from Abingdon since the war. As the V8 was also the fastest production MG, and one of the best handling, it immediately became a collector's piece as soon as they stopped making them in July 1976. Seems like we never know how good a car is until it's gone.

You'll have to pay up to £4000 for a really good new one now, the price of a new

MGB and double that of the equivalent four-cylinder made at the same time. Nearly half

(1072) of the V8s made had a chrome front - a body that looked exactly like that of the

equivalent MGB GT; the rest were the rubber bumper model made from October 1974 to meet

short-sighted U.S. Federal safety regulations. These later V8's also suffered from a spot

of penny-pinching in that British Leyland omitted to fit anti-roll bars front and rear to

make up for the deterioration in handling brought about by raising the ride height to help

meet the new bumper regulations. Actually, all the production MGB V8s had a slightly higher

ride height because they had fatter 175-section tyre and alloy road wheels against the

four-cylinder's 165 x 14 wires or steel wheels. Apart from a modest sprinkling of V8

badges, their wheels, and slightly higher ride height - giving a more muscular appearance

- were the chief way of telling them apart from the four-cylinder cars, apart from driving

them, of course.

The difference in performance imparted by the V8's all-alloy 3528cc Rover engine was

fantastic. It was good for 124mph, with a 0-60mph time of 8.6sec and standing quarter mile

in 16.4sec against the four-cylinder car's 102mph, 13sec and 18.5 (reduced to 96mph, 14.6

and 20.2 in 1973 Federal specification). Fuel consumption was very good: 25mpg against 27mpg

from the four-cylinder. People just assumed that an MGB with a V8 engine was thirstier than

the lower-powered car and British Leyland did little to quell their fears apart from coughing

up a generous quota of road test cars for the popular magazines of the day and leaving people

to find out for themselves. An advertising campaign emphasizing this point would have done

the world of good for V8 sales, but, then, it was never a popular model in corporate circles.

|

Enjoying this article? Our magazine is funded through the generous support of sponsors like: Mantell Motorsport "Where the Spirit of Driving has a Home!" (Pete Mantell specializes in Ford-based MGB-V8 conversions/parts and powder coating.) |

British Leyland only authorized production in what seems a fit of pique. Down at Abingdon they had been fiddling about with MGB V8s for years. Designer Syd Enever tried all sorts of combinations, including Coventry Climax and Daimler engines when Jaguar joined the fold in 1968. It was obvious that his stiff MGB shell would take a more powerful engine provided it didn't weigh appreciably more than the existing B-series unit's 358lb. The MGC of 1967 had used a modified MGB shell and proved to be a disaster when BMC's redesigned C series 2912cc engine tipped the scales at no less than 567lb. "It should have been half a hundredweight lighter," said John Thornley, the man in charge of MGs at the time. Rover's magnificent alloy V8 weighed about 320lb. (and slightly more than the B series engine when equipped with beefed-up ancillaries), but did not come into the reckoning for a variety reasons in 1967: Rover needed all the engines they could produce and fitting it to an MGB would have increased the demand considerably. Beside MG and Rover were not yet in the same commercial group, British Leyland.

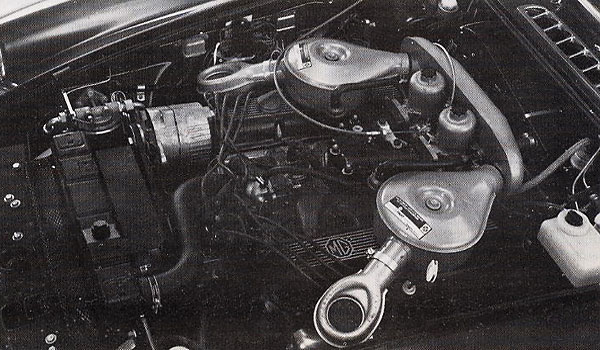

Rover's ex-Buick light-alloy V8 shoehorned neatly into the MGB's engine bay:

It weighed 250lb less than the straight-six C and gave more power.

The history of Rover's wonderfully versatile engine is fascinating. This pushrod unit

had been developed from a General Motors engine used between 1960 and 1963. The Americans

stopped production when their thin-wall iron casting techniques improved sufficiently to

make the lightweight V8 an oddball in their range. It was spotted accidentally by a Rover

executive and built under license for the company's saloons and later the Range Rover.

Fitting it to the MGB in 1967 would have involved considerable expenditure in meeting

anti-emission regulations and could have caused problems with General Motors who did not

want to see a cheap, and fast, MGB competing with their Stingray, and using one of their

engines.

(British V8 editor's note: Fitting a discontinued GM engine into MGC wasn't a realistic

option when the MGC was being developed. Remarkably, many people fail to note the obvious

American alternative: the small-block Ford V8 engine that was already being used in

British-made Sunbeam Tigers. The timing could have worked out so well: with purchase of

Sunbeam by Chrysler, Ford had reason to look for another customer. The Ford 289 V8 in

Mark-2 Tigers was 150lbs. lighter than an MGC six, yet it produced far more power and

torque. Ford had to comply with the same anti-emission regulations mentioned above, so

MG's engineering costs would have been largely mitigated. The MGC chassis provided a

stronger, stiffer platform than the Sunbeam Tiger, superior handling, and a GT bodyshell

option. MG's much larger dealer network, compared to Sunbeam, would have made an MGC with

factory-installed Ford V8 a great success.)

However, during 1970, when MGC production had been abandoned, a garage proprietor from

Kent, Ken Costello, who had raced MGBs, started experimenting with fitting the Rover V8

engine to the cars of customers who wanted more performance without the handling problems

of the MGC. It was an extraordinarily attractive unit, producing 185bhp at 5000rpm in the

10.5:1 compression ratio form used in Rover saloons and 137bhp in the 8.25:1 Range Rover

form. The torque, 226 lb. ft. was massive and proved to be something of an Achilles heel

to the Costello V8s when mated with the standard MGB all-synchromesh gearbox it was rather

too much. However, other advantages of the installation tended to blind people to this

problem; a variety of stiffer rear springs were available to provide tramp-free take-off

and the performance was phenomenal - 130mph, 0-60mph in 7.8sec. and the standing quarter

mile in 15.8sec with the heavier GT version. This weighed 20.5cwt with a fiberglass bonnet

reshaped to clear the Rover engine's twin SU carburetters. Roadsters weighed around 1cwt

less and were slightly faster.

There was one additional problem with the roadster in that its shell was not really stiff

enough to take all that torque. These bespoke Costello cars retailed at around £2600

in 1972 with the larger (9.5 in.) MGC clutch and higher rear axle ratio (3.07 against 3.9:1);

more than double the price of a standard MGB GT at the time. Nevertheless, they received

considerable publicity and demand was quite high. After the debacles of the MGC, British

Leyland were stung into action. They stopped supplying new engines to Ken Costello and

started work on their own MGB V8. Costello soldiered on with exchange units and the odd

errant Buick, but there was no hope of him setting up a production line.

Enjoying this article? Our magazine is funded through the generous support of readers like you!

To contribute to our operating budget, please click here and follow the instructions.

(Suggested contribution is twenty bucks per year. Feel free to give more!)

Meanwhile Abingdon ran up their first MGB with Rover power in December 1972; it was an

extraordinarily neat conversion of the GT shell using the Range Rover version of the V8

and SU carburetters as they considered that its 137bhp and 193lb. ft. of torque were

quite sufficient for the gearbox and rear springs, which were stiffened in any case.

A special inlet manifold was used so that the carburetters could be squeezed under a

standard bonnet (British Leyland had come in for considerable criticism from America

for the bulges on the MGC bonnet) and a higher ratio overdrive gearbox with 3.07:1 rear

axle. Fuel consumption was thus improved to around 25 mpg against Costello's lower-geared

cars, which returned about 18mpg.

Some slight modifications were needed to the cars' shells (mostly rounding off corners

in the engine compartment) and it was decided to standardize this with the four-cylinder

machine. Thus, all the MGBs from mid-1973 when V8 production got under way were built

with this new shell. Only the GT version was built by the factory, however, who were

worried about the roadster's rigidity. It was intended to export the MG V8 to America

(where the vast majority of MGBs were sent) and seven left-hand-drive cars were built

in the development department at Abingdon alongside ten right-hand-drive ones in

January and February 1973. However, the same situation that had gone against the MG V8

in 1967 still applied and there was the problem that there was hardly sufficient room

under the bonnet for America's increasingly bulky emission equipment. Eventually, the

MGB GT V8 was announced in right-hand-drive form only in August 1973. Two of the

left-hand-drive cars were sent to the New York Motor Show and were returned to Abingdon

later to join the other five, which were retained until 1974 and 1975. Six were then

sold to European customers and the other went to British rallyman Michael Pearson, who

campaigned it with considerable success. Swiss MG enthusiast Thomas Studer bought one

of the other left-hand-drive cars and races that on the track.

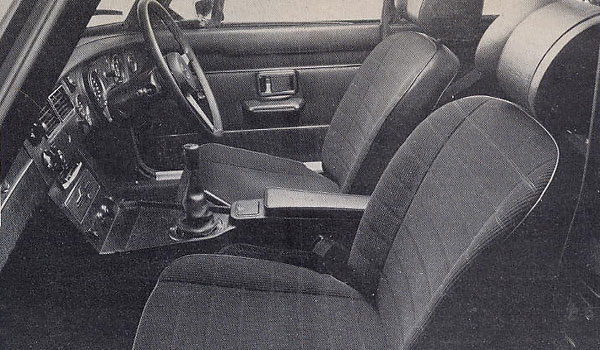

Interior of the first '73 MGB V8 - simple to the point of being austere,

but comfortable and cosy with it. Seat had plaid cloth upholstery.

Unfortunately, just as the MGB GT V8 was launched, Britain was about to lurch into a

deepening energy crisis and this, with the difficulties in building enough V8 engines,

kept production down. The price didn't help either: £2294 in the United Kingdom

against £1547 for a four-cylinder MGB and only £1824 for the nearest

competitor, the Ford Capri 3000 GXL. The V8 could have been offered for £1800-1900,

but British Leyland figured that Costello's had sold for much more and there

was a market for a limited amount at the higher price. This was not to prove the case,

however, and production petered out (1069 cars built in 1973, 854 in 1974, 489 in 1975

and only 176 in 1976) before the V8 was no more. One more factor that went against it

was that British Leyland decided to drop the MGB GT in America in 1975 to give their

new hope, the Triumph TR7, a clear run.

As with any MGB, you have to check for rust in the sills and wings of an elderly example

(this can be quite easily prevented by modern rust-proofing agents); with the V8s be

especially wary of a noisy gearbox (even in its 137bhp standard form, the box was on

the limit of its capacity), and anything other than a very smooth engine. The switches

on the V8's twin electric fans are notoriously unreliable and can lead to unexpected

overheating with subsequent engine trouble.

Such is the interest in the renaissance of the MGB V8 that rumour has it that British

Leyland are about to make more. This has been hotly denied by official sources, who

make the point that the four-cylinder cars are still selling so well (and pass the

half-million production figure this year) that they have their work cut out producing

enough of them!

Chatham's open V8

After the demise of the production cars, there was still a certain demand for the MG

V8, and Costello continued to convert the odd car. Another garage proprietor and

racing driver, John Chatham wondered what he could do to alleviate the situation.

What the enthusiasts really wanted, he reasoned, was an open MG with V8 performance.

With the considerable experience of running and building Big Healeys and ex-works

MGCs behind him, Chatham decided to use the MGC shell for his prototype. This was

much stiffer than that of the MGB roadster and he had lots of ex-works parts in any

case. He then obtained a modified V8 engine giving around 200bhp fitted with a

Costello Weber conversion, and mated it to an MGC gearbox. To get over the MGB V8's

gearbox problem, he fitted works straight-cut gear clusters and competition overdrive

on third and fourth with a 3.7:1 limited slip rear axle, 14in. x 7in. Minilite wheels

and low-profile tyres. Suspension and braking were uprated to competition standards

and the performance was shattering.

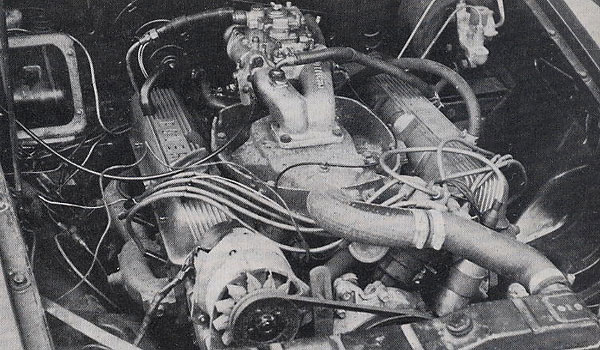

Chris Harvey's Chatham-converted V8-engined MGC roadster on Minilite wheels and 7in.

tyres. With modified 200bhp engine, the car will sprint to 60mph in under 6 seconds.

When I first tried the car soon after it was completed in Bristol in February 1978

it recorded a tyre-smoking 5.8sec 0-60mph time with an unmentionable top speed! Like

all MG V8s, its 50/50 weight distribution gave it dream-like handling and it took no

sales talk from Chatham for me to buy the car. In 35,000 miles since then it still

retains the V8's turbine-like power and has shown me why these machines are sought

so avidly be collectors.

You can still buy a new MGB GT V8. After converting a number of second hand cars for

customers, Chatham built his first all-new V8 in January. Using a Rover SD1 engine

and five-speed gearbox with Triumph TR7 C8 Offenhauser manifold and Holley four-choke

carburetter, plus Minilite wheels, this machine cost £8200, less the value of

the new four-cylinder engine, gearbox, wheels and tyres removed.

BritishV8 Magazine has assembled the largest, most authoritative collection of MG "MGB GT V8" information you'll find anywhere. Check it out! Access our MGB GT V8 article index by clicking here.