Upper left: the resistance-wire wrapped bimetallic element of an old-fashioned thermal voltage stabilizer.

Lower right: a solid-state electronic voltage regulator that can be used to replace it.

How To: Replace Your MGB's Lucas Thermal Voltage Stabilizer

Install a Solid State Regulator Inside the Lucas Case

as published in British V8 Magazine, Volume XVI Issue 2, September 2008text by: Curtis Jacobson

photos by: Jim Miller

Notes: this article references MGB equipment, schematics, etc., and the information may or may not be transferable to other vintage British sports cars.

Background Information

Are you still using your MGB's original fuel level and coolant temperature gauges?

Unlike aftermarket gauges, these two old-fashioned gauges are simple "single-coil"

devices. To work properly, they need to be used with an external "voltage stabilizer".

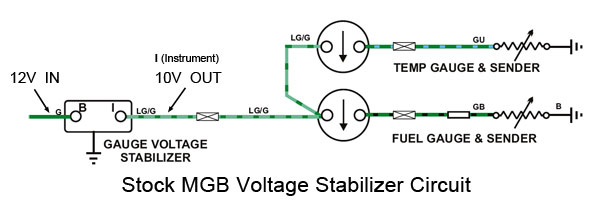

Please refer to the schematic drawing below ("Stock MGB Voltage Stabilizer

Circuit") for a quick illustration of how these instruments are wired into their

respective circuits. According to the schematic, the gauges are designed to recieve

a supply voltage of 10V (constant) from a device called a voltage stabilizer. The

fuel level and coolant temperature sensors, downstream of their respective gauges,

are connected through their mountings to chassis/ground. The sensors act like

"variable resistors" - the resistance changes with fuel level or coolant temperature

respectively.

Reading from left to right, the first thing that we notice is that the voltage

stabilizer itself is nominally provided 12V power. However, we know from experience

that the voltage "in" isn't so stable or predictable! Any number of things could

affect the supply voltage available including the battery's state of charge, the

output of the generator or alternator at any given moment (which may be affected

by engine RPM), and whether various loads on the system are on or off.

Regardless of how unstable or unpredictable the 12V power supply is, the

voltage stabilizer's purpose is to iron things out. One conclusion you

might reasonably take from the schematic is that: "If the voltage stabilizer

provides more than 10V both gauges will read high, and if the voltage

stabilizer provides less than 10V both gauges will read low." So, the voltage

stabilizer provides the gauges a stable, accurate 10V input to work with, right?

Not exactly! The original MG voltage stabilizer doesn't actually regulate

voltage at all. Instead, it cycles power "on" and "off" to achieve an average

voltage over time of about 10V. If you take an old-fashioned voltage stabilizer

apart, you find a bimetallic element with a resistance wire wrapped around it,

much like an "automatic reset circuit breaker". Heat in the resistance wire causes

the bimetallic element to bend, rapidly opening and closing a set of contact points

and thus switching between the nominal supply voltage of 12V and zero volts.

That suits your old MGB gauges fine because your gauges have a lot of dampening

built into them. If your gauges are sufficiently damped, you may not see their

needles constantly wiggling as the voltage stabilizer chatters on and off; you'll

only percieve the "average" readings that they're showing you.

By modern standards, thermal voltage stabilizers aren't particularly accurate

or consistent. (For example, their output varies a lot between summertime and

wintertime because their accuracy is affected by ambient temperature. Their output

also varies as the bimetallic element fatigues and as their internal contacts grow

dirty.) If your voltage stabilizer needs replacement anyway, or if you just want

to dramatically improve the accuracy and consistancy of your fuel level and coolant

temperature gauges, you may want to consider converting to a modern solid-state

electronic voltage regulator.

Important note: if you replace your original MGB gauges with aftermarket gauges,

you need to remove the old-fashioned thermal voltage stablizer. Modern gauges have

a dual-coil design which provides accurate information regardless of supply voltage,

but which may not be able to accomodate the abrupt on/off cycling of a thermal

voltage stabilizer.

Shopping List

Solid state voltage regulators are inexpensive, but they may be difficult to find

locally. The easiest places to purchase them are online. "Google" the part numbers

to identify potential suppliers.

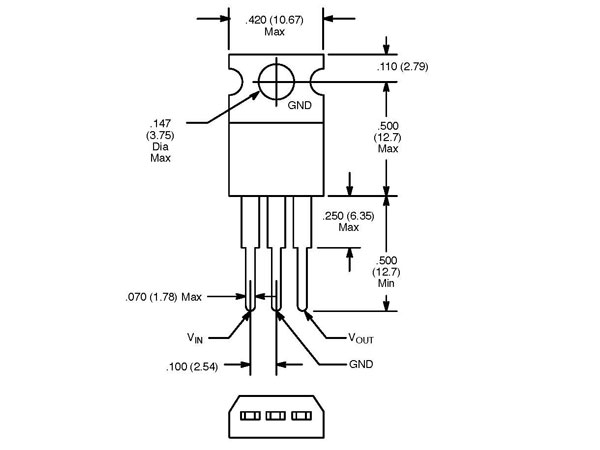

National Semiconductor's "LM2940T-10.0" and NTE Electronics' "NTE1953" are

low dropout (LDO) solid-state voltage regulators. If you supply either of them

with a DC voltage between 10.5V and about 30V, they will provide a constant output

voltage of 10.0V. Similar to an old-fashioned bimetallic voltage stabilizer, they

can't boost voltage: so if the supply voltage drops to below about 10.5V, these

LDO's will "dropout" and simply pass through whatever supply voltage is available.

Note: there are other alternative voltage regulators that could also be used. One

example is Texas Instruments' part number "UA7810CKCS" (a.k.a. "7810" or "LM7810")

which frankly you're probably more likely to find at your local Radio Shack. The

main advantage of the National Semiconductor or NTE Electronics devices is their

somewhat lower dropout specification.

Optional: a small LED lamp and a 1000 ohm resistor.

Also needed: just a few basics including a soldering iron, solder, about six inches of

insulated wire, heat shrink tubing (or possibly electrical tape), etc.

Directions

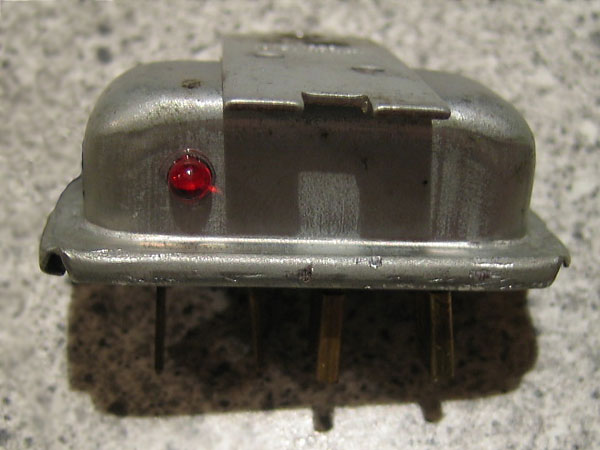

1. Disconnect the car's battery and remove the original voltage stabilizer

from the car. (Note: the voltage stabilizer is mounted on the drivers-side

firewall just above the steering column.)

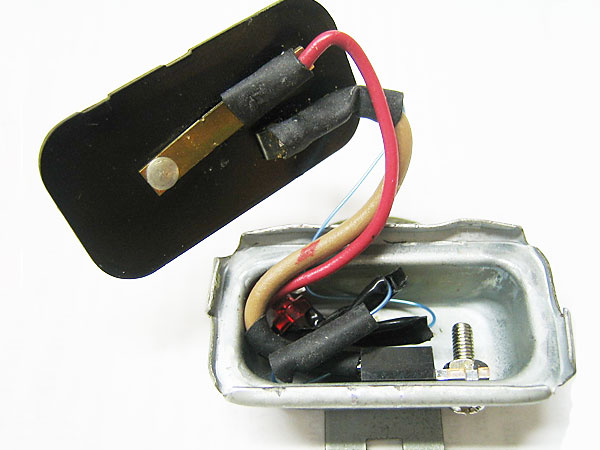

2. Open the voltage regulator by carefully prying back the tabs that clamp

the metal cover to the plastic base.

3. Cut and remove the old bimetallic regulator mechanism, being careful to

leave enough of the two terminals for soldering wires onto them later.

4. Prepare your solid-state voltage regulator by cutting off the center of

its three terminals. (This terminal is nominally a "ground" connection, and it

would be redundant with the mounting tab in our installation. They're connected

internally...)

Enjoying this article? Our magazine is funded through the generous support of readers like you!

To contribute to our operating budget, please click here and follow the instructions.

(Suggested contribution is twenty bucks per year. Feel free to give more!)

5. Using a short length of wire, jumper between the solid-state voltage regulator's

VIN (12V in) terminal to the "B" terminal on the plastic base.

Carefully solder both connections.

6. Using a short length of wire, jumper between the solid-state voltage regulator's

VOUT (10V out) terminal to the "I" terminal on the plastic base.

Carefully solder both connections.

7. The LED indicator is optional. It is connected between the 10V OUT

terminal and ground through a 1000 Ohm resister.

8. To function properly, the solid-state regulator must be electrically

well-grounded to the rest of the vehicle. Accomplish this by (first) connecting

it to the voltage regulator's metal cover with a machine screw and nut. Note:

the voltage regulator itself must in turn be grounded to the car by its mounting.

If the fasteners are corroded or dirty, they should be cleaned at this time.

Disclaimer: This page was researched and written by Curtis Jacobson and Jim Miller. Views expressed are those of the authors, and are provided without warrantee or guarantee. Apply at your own risk.

Photos by Jim Miller for British V8 Magazine. All rights reserved.