�

�

Clive Wagerfield's Original MGB GT V8 Prototype (Number "096")

� as published in BritishV8 Magazine, Volume XVII Issue 1, July 2009�� Owner: Clive Wagerfield

� City: Buckinghamshire, UK

� � Model: MGB GT V8

� Engine: Rover 3.5L V8

�

�

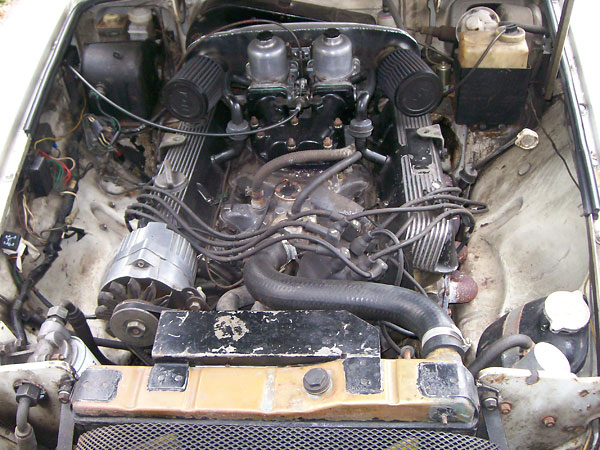

The first five MGB GT V8 prototypes were built late in 1972 and started life �

as standard 1800 GT's. They were removed from the assembly line prior to �

their four cylinder engines being fitted, and they went to the Development �

Department shop where they were completed to V8 specification. This included �

significant modifications to the engine bay including: relocating the radiator �

forward, recontouring the inner fenders, and modifying the firewall at the front �

corners of the transmission opening.�

�

My car, number "GD2D1 96 G", was one of these five prototypes. I purchased the car �

from Norman Ward, who bought the car directly from MG Cars at Abingdon on April 28, 1976. �

Norman Ward's father, Robert Ward, was Plant Director at the MG assembly plant and he �

recommended the car to his son when it came up for release. When I purchased the car, �

I also got the original receipt which reveals that Norman paid the princely sum of �

£875. This original MGB GT V8 prototype is registered "MMO 229L" - just as it �

was when Norman purchased it! �

�

�

�

"The Car Number is stamped on a plate secured to the RH wing valance adjacent to the filter."

�

�

�

The fiberglass air dam and rally lights were installed by previous owner Norman Ward, although when

�

Norman picked the car up from the factory, it had extra headlights fitted where the spotlights are now.

�

Curiously, the switch selected either left or right but not together! The car came with the same

�

Dunlop composite (aluminum hub / steel rim) wheels that were used on production MGB GT V8's.

�

Although standard on production MGB GT V8's, this prototype never had SundymTM tinted windows.

�

�

Traveling incognito: MGB GT V8 prototype, viewed from the rear.

�

�

Although Norman didn't research or document the car's unique history, I've been able �

to verify some things about the car and its use by the MG development team. One �

important fact is that "number 96" was never fitted with V8 badges! Without those �

badges, of course, it could travel a little more inconspicuously on public roads. �

�

And travel it did! Prototype "096" was used for engine evaluation and speed trials. �

The first reference I found for this appears in the book "MG" by McComb. Norman Ward �

tells me the following excerpt was verified by both his father and the late MGOC V8 �

Registrar's Historian, Geoff Allen:�

�

"Although no figure for maximum speed in overdrive was quoted, a perfectly �

standard car had been taken to France for tests by Alec Hounslow, foreman �

of the development department workshop and one-time riding mechanic to �

Nuvolari. He got a genuine 222 kph maximum, converted from kilometers to �

miles, and realized with some astonishment that he was traveling at 138 mph. �

In the words of MG's former chief, John Thornley, 'The V8 was a quite �

stupendous motor-car. From my own experience, when you were doing 100 mph �

in overdrive top and put your foot down on the accelerator, you got a push �

in the back. Now, that is motoring!'"�

�

Subsequently, I've been very fortunate to make personal contact with MGB legend �

Don Hayter who seems pleased to help fill in more details. Don recalls that due to �

a lack of suitable roads in England, Alec Hounslow and Mike Hearn took prototype �

"096" to France for high speed assessment using the then-new "A1" autoroute (a.k.a. �

"l'autoroute du Nord" or in English "the Northern Motorway"). Don has spoken to �

Mike and apparently he remembers much of that event, so we'll update this article �

as details become available.�

�

�

Is this a North American specification engine?

�

�

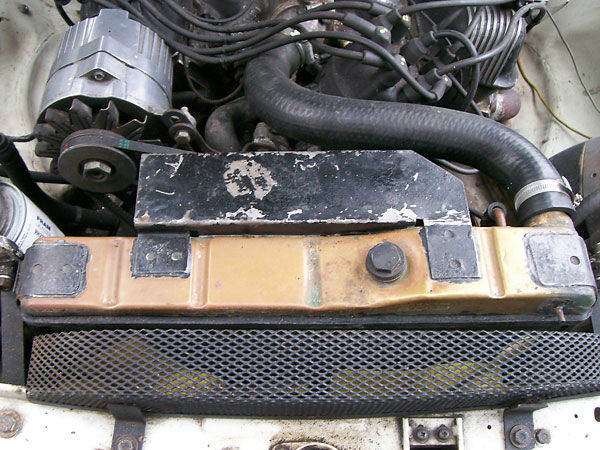

The radiator has a fan guard, although the engine-driven fan was apparently removed by

�

the Development shop. (It was made redundant by the dual electric fans, also shown.)

�

� The stamped engine serial number plate on this car is "49000004", whereas the � production V8 engine serial numbers started with "486" followed by a further five � digits. What about the other prototypes? Remember that there were five Development � Shop built prototypes, followed by line-built "Pre-Production" cars (which were also � "prototypes"). It's been documented elsewhere that shop built left-hand drive prototype � "97" was fitted with engine number "48600002". The engines in left-hand drive � prototypes "98" and "100" had engines with serial numbers marked "EXP 107" and � "EXP 103" respectively. After that, the first four line-built left-hand drive � prototypes ("101", "102", "104", and "105") were fitted with engines prefixed � (like mine) by "49". �

��

�

The engine serial number on prototype number 96 is 49000004.

�

(Note: this surface is adjacent to the transmission's bellhousing. Notice that no adapter

�

plate is used for mounting the transmission. The bellhousing is integral to the transmission case,

�

just as on the production MGB GT V8, but quite different from the production 1800cc MGB.)

�

� According to former British Motor Industry Heritage Trust archivist Anders Clausager, � the engines for the left-hand drive cars were built to North American specifications � and were to be fitted with emission controls. Was Clausager referring to just the � "EXP" engines or to the "49" engines as well? This is a particularly intriguing question� because a North American spec 1972 Rover 3500S saloon would have received a 10.5:1 � compression ratio engine (rated 184hp at 5200 rpm and 226ft.lb. of torque at 3000rpm.) � In other words, it seems that MG's original plan may have been to produce a more � potent MGB GT V8 for export.�

��

At any rate, there seems to be circumstantial evidence to indicate that the engines �

for prototypes 96 and 97 were inadvertantly mixed up. Car number 96. as far as I can �

ascertain, is the only right-hand drive car to be fitted with one of these �

'North American' engines. I wonder why?�

�

To provide clearance for the exhaust manifolds, on the prototypes, sheetmetal �

was literally cut out and replaced with welded-in, formed, patch panels. �

�

�

In this photo, you can clearly see some of the weld-line on the inner wing. Interestingly, this prototype

�

was apparently built with fabricated/tubular headers in lieu of production-style cast iron exhaust manifolds.

�

�

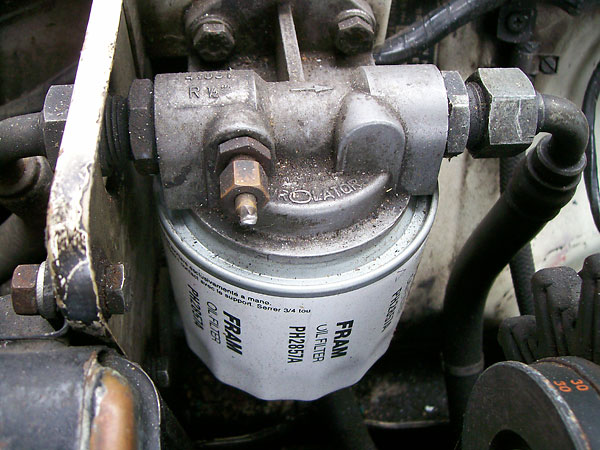

A mounting bracket for the remote oil filter was welded-in too. Note: early MGB GT V8's had the

�

take-off for the oil pressure gauge here. Later, it was relocated to the oil pump body for a

�

faster reading. On this prototype, the take-off has been crimped shut.

�

�

How else was the bodywork modified to accommodate the V8 engine? Firstly, the bonnet �

was re-tooled to give greater curvature. This became standard on all MGB's. The mouth �

of the gearbox tunnel was also enlarged to allow for the new bell-housing arrangement.�

�

Once MG began testing the MGB GT V8 prototypes, it quickly became apparent that significant �

torque reversals could occur when switching in and out of 3rd overdrive. It would be easy �

for these reversals to damage an already fragile gearbox. Both Don Hayter and separately, �

the late Geoff Allen recall that my car suffered catastrophic gearbox failure during testing. �

Over the Easter holiday of 1973, an "inhibitor" was fitted to prevent entering overdrive from �

third gears. The gearbox was also modified on first gear. There are many early MGB GT V8's �

that still have overdrive on both 3rd and 4th. The factory's policy was "if it isn't broke, �

don't fix it", but overdrive was blocked from 3rd gear fairly early in production. �

�

�

�

On this prototype, MG installed the rare 'tapered slot' steering wheel which was used on all MGB's

�

from August 1972 through June 1973. When the V8 went into serial production, they instead used a

�

special wheel with solid spokes that featured "indented slots".

�

�

Like all production MGB GT V8s, this car has a collapsible steering column.

�

(Home market 1800cc MGB's didn't get collapsible columns until September 1974.)

�

�

The speedometer and rev counter (aka tachometer) on this prototype are identical to production MGB GT V8's.

�

Their 80mm diameter is smaller than regular home-market MGB's to accomodates a collapsible steering column.

�

�

The speedometer reads to 140mph and the rev counter indicates a "redline" of 5250rpm.

�

�

The oil pressure gauge reads to 60psi. Later MGB GT V8 gauges read to 80psi, and then to 100psi.

�

To its left is the choke control. Later MGB GT V8's had a T-handled knob, labeled "Choke" and "Lock".

�

�

The OD switch is on the left-hand stalk that also incorporates the windscreen wipers.

�

�

Vintage 8-track "integrated circuit" stereo radio.

�

�

�

The upholstery is standard 1972 (1800cc) GT spec. As the car is Glacier White, the seats

�

are in Navy. They have a brushed nylon centre panel with vinyl sides. This configuration

�

was only used in 1972, and its different from production MGB GT V8's.

�

�

�

(Note: This is just an evaporative system canister... it collects gasoline vapor, which is

�

then routed back to the carbs. An S.U. fuel pump is mounted down by the batteries.)

�

�

The disc brake rotors are 10.7" diameter x 1/2" thick, which may indicate that

�

MG decided to install uprated disc brakes early in the development program.�

� �

��

� BritishV8 Magazine has assembled the largest, most authoritative collection of MG � "MGB GT V8" information you'll find anywhere. Check it out! � Access our � MGB GT V8 article index by clicking here. �

�