Peter Linn's Holden V6 Powered 1955 Austin Healey 100

as published in BritishV8 Magazine, Volume XVIII Issue 1, December 2011Owner: Peter Linn

City: Brisbane, Queensland, Australia

Model: 1955 Austin Healey 100

Engine: Holden 3800cc V6

Conversion performed by: Bob Wittred and Peter Linn

Peter Linn Tells the Story of "The Holden Healey"

Austin Healey 100 chassis number BN1-223926 rolled out of Austin's Longbridge factory

on February 10, 1955. The car was Healey blue with blue trim. It was dispatched to

UK Motors in Brisbane.

In the mid-1980s, Queenslander Bob Whittred came across the remains of the car on a

farm near Ballina New South Wales, where it had sat for many years following an accident

in which the front left corner was extensively damaged. The drivetrain and most of the

running gear were long gone.

Bob paid $450.00 (Australian) for the sad remains, and commenced what by any standards

was a mammoth task of restoration. This involved replacing the front half of the chassis

rails, crossmembers, much of the body sub-frame and repair or replacement of most of the

outer body panels. BN2 rear guards were fitted, and the car was prepared for final panel

work and paint. Bob found a Wolseley 6/110 sedan parts car, and used its front suspension

including disc brakes with booster, and its rear axle with 3.54 differential. (These

parts are all very similar to later Austin Healey 3000 running gear.) For an engine,

Bob initially planned to install a Rover 3.5L V8, but he found this to be a tight fit,

so instead sourced a 40,000km V6 from a Series 1 Holden Commodore. Like the Rover V8,

Holden's "3800" engine (which is similar to Buick's 3800 ninety-degree, iron-block V6,

except assembled in Australia,) is closely derived from Buick's 215 cubic inch aluminum

V8, first introduced in 1961. The engine came with a 4 speed automatic gearbox.

The Holden motor was a good fit. It's smaller and lighter than the original Austin engine

and it was easily mounted lower and further back in the chassis. It produces 165 bhp in

standard tune.

The restoration stalled in the mid-'90s, and some 15 years later Bob decided to sell it.

I'd been looking for a standard-bodied 100 project. As much as I like the Ward Special,

I wanted to get back to open air motoring for the first time in many years. (I had last

driven my MG TD before leaving the UK in 1982.) I'd looked at a couple of other projects,

but for various reasons the deals didn't go through. Bob's car appealed to me as soon

as I saw it; it came complete, straight and with many new parts. I particularly liked

the wheels Bob had made. He used 100/6 steel centres with Chrysler rims. To suit the Healey

they have different offsets front and rear, and non-functional knock-on spinners to give

the appearance of Dunlop peg drive wheels like those worn by the Healey record breakers.

Bob had also made a very nice wood-rim steering wheel using the original centre and spokes.

After not very much thought and a fairly brief discussion over price (we both had the

same figure in mind) the car was mine. It arrived home on a trailer in July 2008.

Because I was partway through restoring a 1963 Series 2A Landrover, I didn't start working

seriously on the Healey until well into 2009. I did apply for the Heritage certificate

though, using the body number as the chassis plate had gone.

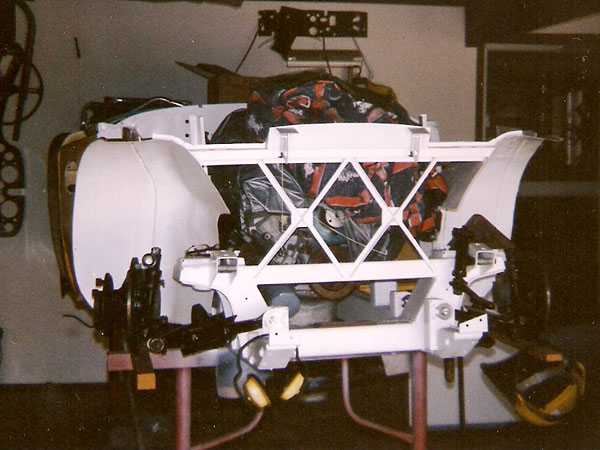

My intention was to paint the car dark BRG over Old English White. Bob had planned to paint

it in 100S colours of OEW over Lobelia blue, hence the white chassis.

Another early task was to get a Queensland Transport approved compliance engineer to

look at the car to make sure I could proceed with it in view of the modifications. He gave

me a list of upgrades that would be required in order for it to be approved with the

replacement motor. These included dual circuit brakes, two speed wipers, a demister and

retractable seat belts. One item that could have buried the project was that a collapsible

steering column is required if the replacement engine is more than 45% bigger in capacity

than the original. This looked likely on the rounded figures for the two motors, but using

the exact figures from the factory specifications, it came out to 42.5%.

At this point I started looking at finishing off the mechanical side of things. This included

the cooling system and the brakes, including separating the front and rear circuits. I used

a Datsun 240Z master cylinder courtesy of George Goss, with a PBR booster operating on the

front circuit only. I had to make up brackets for the front hoses, for which I used Range

Rover parts. There was no handbrake lever, so I "borrowed" the one from the above mentioned

Landrover which is very similar in appearance to the Healey one, once chromed. My Series 3

Landrover donated its two speed wiper motor, and a 12 volt camping hairdryer became the

demister! Hardy Spicer made a tailshaft using the Healey rear and Holden front yokes, with

larger diameter tube. I had all the brake components checked over and refurbished as

necessary as they had sat for 15 years.

Bob had fabricated a very nice 85 litre alloy fuel tank, but had not had it welded together,

so I had it TIG welded. He also had a nice Aston type quick release filler cap, which he had

intended to use in the normal place inside the boot. I though this was a shame, so rearranged

thing so that the filler was on the rear shroud. The fuel system uses the Holden in-tank pump

and out-and-back fuel lines for the fuel injection system.

I considered looking for a 5 speed manual transmission, but on second thoughts decided against,

as my wife can only drive an auto and I can only drive one car at a time! Instead I modified

the Holden shifter to disguise it as best I could, and mounted it directly to the transmission.

Another club member provided a fibreglass centre shift tunnel cover which I modified to suit.

The one thing I wasn't keen on that Bob had done was the wooden dash incorporating the Holden

instrument panel. Bob had though this would make it easier to wire the computer-driven motor,

but discussions with the specialist firm V6 Conversions and Lionel Otto Instruments in Brisbane

suggested that original appearance gauges could be used. Bob had provided an original dash

panel, a speedometer (gold faced), a fuel gauge and a 3-3/8" VDO tachometer. I already had a

temperature gauge and oil pressure gauge (bought for $2.00 each at a swap meet). I took all this

to Lionel Otto's, who put a black 140mph face in the speedo and rebuilt the fuel and temperature

gauges. It turned out that the VDO tachometer wouldn't work with electronic ignition, so Otto's

built an electronic tachometer from parts they had in stock. The result is an original-looking

set of instruments, except for separate oil pressure and temperature gauges. V6 conversions

proved very helpful, also supplying a cable-drive adaptor for the speedo, and an idler pulley

to replace the power steering pump.

By October 2009, I was getting close to the point where the motor could be reawakened. This meant

wiring, which was beyond my rudimentary electrical abilities. The ECU and main engine compartment

loom were in place, as was the loom to the rear of the car, but the rest needed doing. I obtained

a Holden relay box and fuse panel from the local wreckers, then the car went to a local auto

electrician - Bashi's. They did a great job and a week or so later it was a case of "it's alive!"

It was a great feeling to drive the car off the trailer and up the driveway for the first time.

I'd already lined up with Peter Janetzki, a Queensland club member, to do the final panel and paint

work. My son in law was able to obtain paint at a very reasonable price. The colours are 1950s

Jaguar BRG (a very dark British Racing Green) and OEW. (Old English White is a creamy off-white.)

I could now assemble the chromework etc, most of which was new and came with the car. There are

no bumpers which I prefer, except for a small "nudge bar" at the front that Bob had made, and I

had chromed. Bob had also cast some brass "3000" badges, one of which I modified to read "3800"

and had chromed for the grille. I bought a nice pair of Hella spotlights on Ebay, where I also

found some rear indicator units to fit the reflector pods. I have amber indicators at the front

too in place of the side lights, which are now in the headlamp units. A local saddlery provided

the bonnet strap and spare wheel retaining strap.

I bought a pair of Mazda MX5 seats, which fit well and are fully adjustable, even if the high backs

don't look quite right. I managed to find vinyl to match the biscuit colour of the seats, and

stone coloured carpet. Bob had already made door and footwell trim panels, so it was a matter of

covering these and fitting carpets. I blanked off the spare wheel slot from the boot and covered

the area behind the seats in carpet. I did all the easy bits of trimming myself, a local trimming

firm - Retro Recovery - did a great job of the difficult bits, especially the tunnel cover.

So now it was crunch time, back to the compliance engineer to see if that "blue plate" was forthcoming.

This was the car's first road outing of any length. I was amazed at how "together" it seemed

straight out of the box. It handled beautifully (it has telescopic shocks all round and 3/4

degrees of negative camber on the front). Although the Michelin 185/65-15 MXT tyres originally

on the car were unused, they were 16 years old so I had replaced them with similar section Kumhos.

However, the car started overheating again during brake testing, and also began cutting out. I got

half way home before it cut out altogether, and we made the rest of the trip on a tilt tray!

However, there was little I had to do to satisfy the compliance engineer, and after finding a bit

extra ground clearance under the exhaust, fitting bigger reinforcement plates under seats and seat

belts, getting the speedometer recalibrated and installing a shift indicator, the car passed compliance

inspection. On March 16th 2010, the car was on the road for the first time in, probably, 40 years!

I've since replaced the 12" cooling fan with a 16" one, which has resolved the overheating problem.

The cutting out when hot issue still remained, due probably to a faulty crank angle sensor, which has

now been replaced. The problem has occurred once since, and it seems that cavitation of fuel when

hot may be the cause.

Next on the "to do" list is fitment of a tonneau cover, followed by refurbishment of the fibreglass

hardtop that came with the car. I have the rusty remains of hood bows plus some other hood frame

components, but I haven't yet decided if I'll try fitting a soft top.

So: original - no; practical - yes. In keeping with what Donald Healey would approve of? I think so.

After all, they tried the Rolls Royce motor in the 4000 prototypes, at least one of which had an

automatic gearbox. And if the V6 or a similar motor had been available when the A90 unit was going

out of production, would Healey have used it? Minimal chassis modifications needed, nearly twice

the power, smaller, lighter, making a better balanced car? I think I know the answer.

How It Was Done

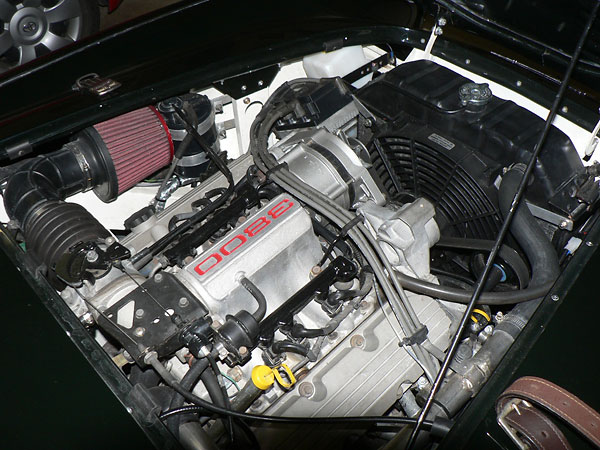

| Engine: | stock Holden (GM) 3.8 litre V6, featuring GM electronic fuel injection. |

| Cooling: | original Healey radiator. 16" electic fan. |

| Exhaust: | stock GM headers. Catalytic converter. Lukey muffler. |

| Transmission: | GM 700/R4 automatic. Modified shifter. |

| Rear Axle: | Wolseley 6/110 3.54:1 (similar to later model non-overdrive Healey 3000). |

| Front Suspension: | fabricated upper wishbones. Stock lower wishbones.

Shorter coil springs to compensate for lighter engine.

Telescopic shock absorbers. |

| Rear Suspension: | stock Healey leaf springs. Telescopic shock absorbers. Panhard rod. |

| Brakes: | (master) Nissan 240Z master cylinder. (front) Wolseley 6/110 front discs with booster. (rear) stock Healey rear drums. |

| Wheels/Tires: | custom fabricated steel wheels comprised of Healey 100/6 wheel centres and Chrysler 5.5" rims. Kumho Solus KH15 185/65R15 tyres. |

| Instruments: | stock Healey except for electronic tachometer. |

| Exterior: | deleted bumpers. |

| Interior: | Mazda MX5 (Miata) seats.

Retractable seatbelts.

Fibreglass hardtop (yet to be refinished). |

| Fuel System: | custom 85 litre aluminum fuel tank.

Holden in-tank pump.

Out-and-back fuel lines for the fuel injection system. |

| Performance: | 165 bhp. Quicker than stock! |

| Completed: | March 16th 2010. 1200 miles driven since completion. |

Engine Installation

Stock Holden 3800 (3.8L) V6, featuring GM electronic fuel injection.

Modified shifter on the GM 700/R4 automatic transmission.

Enjoying this article? Our magazine is funded through the generous support of readers like you!

To contribute to our operating budget, please click here and follow the instructions.

(Suggested contribution is twenty bucks per year. Feel free to give more!)

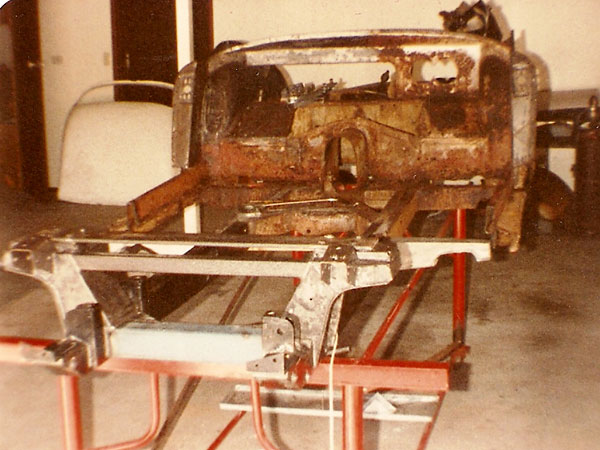

Before Pictures

The car as found in a paddock in New South Wales by previous owner Bob Whittred.

It had sat for many years following an apparently fatal accident.

The drivetrain and most of the running gear were long gone.

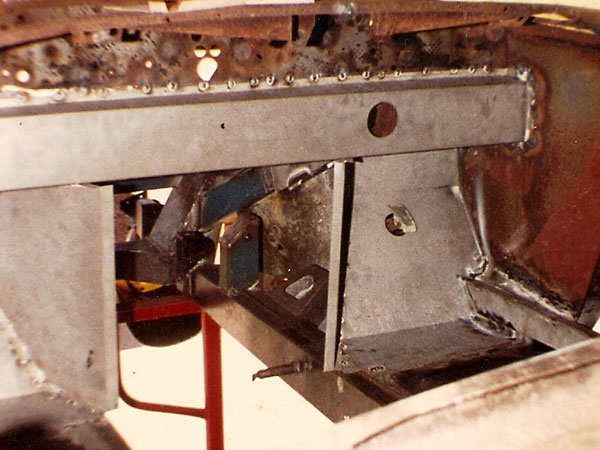

Starting into the rust repairs...

Replaced firewall.

Replaced radiator support.

A temporary wooden dashboard incorporating the Holden instrument cluster.

(This dashboard never saw actual service.)

Repaired Austin Healey 100 bodywork.

Custom bumper bar (awaiting chrome.)

Custom fabricated steel wheels comprised of Healey 100/6 wheel centres and Chrysler 5.5" rims.

Successful test drive!

Primer.

Paint.

Painted: 1950s Jaguar BRG and Old English White.

Custom "3800" grille emblem.

Bob Whittred made this custom wood steering wheel. Mazda MX5 (Miata) seats.

Custom fabricated 85 litre aluminum fuel tank.

The Holden Healey, and its stable mate The Ward Special.