Rick Bondy's Zetec Powered 1961 Austin Healey Sprite

as published in BritishV8 Magazine, Volume XVII Issue 1, July 2009Owner: Richard Bondy

BritishV8 UserID: rickbondy

City: Northville, MI

Model: 1961 Austin Healey Sprite (MkII)

Engine: Ford 2.0 liter "Zetec"

Conversion performed by: owner

Saga of the Zetec Sprite

In 1992 our family was building a second home. There were plenty of cars,

both old and new, and I was doing everything possible to avoid another

automobile purchase. I was pounding nails; not spinning wrenches.

I was buying construction materials, rather than car parts. Of course the

inevitable happened and I purchased another project that could not be

justified to anyone, not even myself. A medical doctor who lived next

door to my father decided to end his SCCA racing career.

The car was a 1961 Sprite Mark II, built to compete in SCCA's "H-Production"

class. A fresh 948 cc engine had just been returned from the engine builder

and was still in the wooden crate. The Sprite had been raced since 1977 and

all of the original metal was in superb condition with the exception of the

front fenders that had been involved in way too much nudging to be saved.

The price was reasonable. We pushed the race car into my father's garage.

The plan to let the car sit vanished within a couple of days and it was

suddenly all over the driveway. We decided to restore the car with a

minimum number of modifications: just enough to drive the Sprite on the

street. At that time, our two daughters were teenagers and we thought

the Sprite might provide a great opportunity for the kids to drive an old

sports car through the rural area around our vacation home. It would

be a very inexpensive project. If the car incurred a little damage here or

there the world would not fall apart.

The Sprite was stripped to bare metal, and new fiberglass rear fender

flares, front fenders, and hood (all from Winner's Circle) were fitted.

We painted the car in black lacquer. The Sprite looked pretty dull in black

without any chrome trim, so a white racing stripe went over the top.

BR60x13 radial tires went on Vega 5 inch wheels and they were covered

in Moon full wheel hupcaps. Cobra seats, lights, and all of the required

stuff just fell right into place. We installed a Painless hot rod wire kit

(#90501), and decided to locate the fuseblock inside the trunk on the

bulkhead.

The car now looked great, but the "full race" motor had an unacceptable idle

and shifting at 9,000 rpm didn't suit driving in the real world (even in an

area with little more than mother nature's critters!) We quickly moved

into "Phase Two".

The next major step was to attempt to civilize the motor. The full race

cam was replaced by an autocross spec unit and a different cylinder head was

substituted to reduce the compression ratio. Predictably the car became

somewhat easier to drive - but it still wasn't much fun. It had high rpm

power, but not enough torque! The little 948cc was somewhere between stock

and full race. It made plenty of noise but the car didn't accelerate as well

as we hoped. The rear axle ratio was changed from 4.22 to 4.55 to one -

and then back to 3.72 to one. All in all, it really didn't change the prognosis.

Although Phase One and Two had transpired with reasonable speed, Phase

Three would require more substantial investment in both time and money. I

was employed at the Ford Motor Company at this time, and I developed an

interest in potentially installing a Ford Zetec 2.0 liter engine in the tiny

Healey. Cosworth Engineering had originally been involved it the engine's

design. It was very robust and it could be modified up to 250 horsepower.

Although peak power usually occurs at 6,000 rpm, it could be spun up to

7,100 rpm. The motor has double overhead cams and four valves per cylinder

in an aluminum head. The Zetec was manufactured in both England and

Germany, in various displacements from 1.3 to 2.0 liters, and it was installed

in Ford products around the globe. Here is the US it was used in the

Contour, Cougar, and Focus. With wide applications in the US, the wrecking

yard prices for complete low mileage examples are cheaper than purchasing

a single performance part for some other makes. (Typical recycler prices range

from $400 to $1,250.) On the other hand, one can purchase a complete, new

"SVT" (Special Vehicle Tuning) engine from Ford.

One negative of the Zetec engine is that it was always installed by Ford

in an "east /west" (transverse) configuration for front wheel drive products.

The engine cants rearward at approximately a 7.5 degree angle to allow for a

low hood line and increased vision line to the pavement ahead. Thus, the oil

sump and oil pickup assembly aren't really well suited for a rear wheel drive

application. There are no side motor mounts, and the engine attaches at the

front through the serpentine belt.

These issues can all be overcome, I knew, because various "Super Seven"

derivatives utilize the Zetec engine. The next step was to visit Great Lakes

Caterham in Milford, Michigan. The owner Jim Constas assisted me in measuring

various configurations. I came to the conclusion that with modifications

the motor might fit, but it was going to be very close. I decided to purchase

a Zetec engine and give it a try. If everything failed, my fallback position

would be to use the engine in a Super 7.

My 2.0 liter Zetec was removed from a wrecked 1999 Cougar with 11,642

miles. The difference between the automatic and manual motors are the

ignition trigger sensor (flywheel-mounted tone wheel) and the length of

the pinion on the starter motor.

Many Super Sevens use a Borg Warner T9 transmission. (It's sometimes referred to

as a Ford "Type 9".) The T9 is a 5-speed manual transmission with overdrive. In

North America the Borg Warner T5 5-speed is more common and inexpensive because

it was used in many more cars including both Mustang and Camaro, but there are

advantages to choosing the T9. The T9 was originally a four speed unit that was

subsequently redesigned with an additional overdrive ratio in a larger tailshaft

housing. Subsequently, it's a very narrow package. It easily fits in the

extremely narrow Sprite transmission tunnel. Unfortunately the only T9 product

imported into the U.S. market was the Merkur. The T9 was widely used in Ford

products throughout England and Europe.

The T9 transmission had different gear ratios for four and six cylinder

applications, and different input shafts too. The six cylinder versions are

generally more suitable for performance applications, due to gear ratios.

I purchased mine from Caterham. (It has the following ratios: 1st = 3.36:1,

2nd = 1.81:1, 3rd = 1.26:1, 4th = 1.00:1, 5th gear 0.82:1.)

To install the transmission, I purchased everything need from the Morris

Minor Center in Birmingham, England. This included the drive shaft

(29.25 inches), speedometer cable, cross-member, and various bits of

incidental hardware. Everything came with great instructions, and the

installation was quite simple. This was in early 2001 and by now these

items are available through various vendors in the U.S. A new speedometer

cable hole was drilled in the side of the transmission tunnel, and the top

of the tunnel was enlarged just in front of the shifter location to

compensate for the increased height of the tailshaft. A new tunnel cover

and boot were fabricated and the shifter was shortened. The shifter location

is perfect.

My order to Caterham included an alloy bellhousing, clutch and flywheel

kit, sump kit, and many other items included in their basic Zetec

installation kit for a Caterham. For the Sprite many items from this

kit were not utilized, plus I went back and purchased other Caterham

pieces along the build process.

The Caterham alloy bell housing and clutch pieces include a number of

fabricated pieces to utilize an annular clutch bearing (aka: HTOB or "hydraulic

throw-out bearing"). For the Sprite, this is terrific since very little

space exists for a clutch release arm. I found out the hard way after two

annular release bearing failures (motor removal) that the capacity of the

stock Sprite clutch master cylinder exceed the hydraulic capacity of the

release assembly. I've finally determined the exact distance the clutch

pedal can travel without blowing the bearing seal, and I've fabricated

a pedal-stop on the floor. Finally no more clutch failures! Looking back,

this was one of the most frustrating events during the development mileage.

The Zetec motor won't fit without some custom fabricating - but with

careful modifications to accomodate engine placement I was able to get

the engine low enough that the hood would close. The Sprite features a

unibody chassis with frame extensions in the engine compartment area. The

frame extensions are stamped sheetmetal with a spot welded flange. This

flange interfered with the width of the Raceline sump assembly which had

been purchased through Caterham. I cleaned and folded the small flange over.

Seam sealer and paint completed the modification. The pan will just fit

between the rails. The oil drain plug is on the passenger side of the

pan. Once the installation is completed, you'll just be able to loosen

the drain. If you want to remove it completely you'll have to loosen

the engine mounts and slide the motor towards the driver's side.

The cast aluminum sump is quite short and allows the engine to fit under

the hood. The engine oil filter will not fit and a remote oil filter was

installed on the cowl. With a Fram HP-1 filter, the oil capacity is 5.75 quarts.

I found that 5w30 oil really does work best. 20w50 racing oil creates

extreme pressure.

The next step to fit the motor between the main rails is notch in both rails

about 4 inches long and a half inch wide and tall. This notch was subsequently

boxed-in with 1/8 inch angle iron. This allows the bell housing to sit low

enough between the rails and insure a proper relationship between the tailshaft

and the differential pinion.

There is a chrome moly round tube roll bar under my Sprites instrument panel.

The tubing extends from the floor up behind the dash and terminates again at

the floor. From each side main front frame rail at the suspension pickup

point tubing extends rearward and ties into this hoop. All of the remaining

SCCA tubing was removed and the car is amazingly rigid.

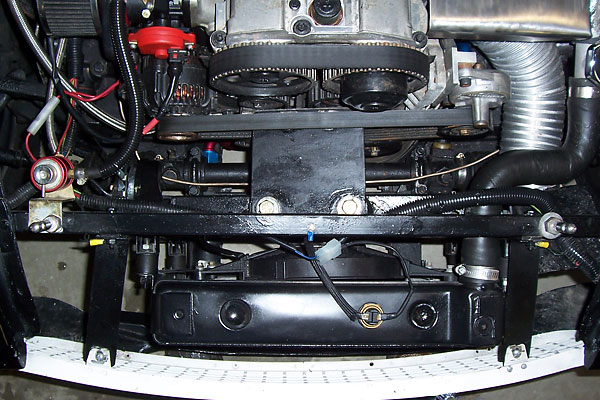

The main front cross member which ties the frame rails together and serves

as the mount for the steering rack was permanently removed. This was required

since there is not enough room for the Zetec oil pan and crank pulley. The

new crossmember was puts the steering rack in an ideal position to avoid bump

steer, and also locates the front motor mounts and the radiator. It is generally

box-like in shape, with the top sloped at 7.5 degrees to mount squarely to

the front to the motor. It was designed to be removable; it simply bolts to the

frame extensions. The motor and transmission are removable now by sliding

them forward on dolly once the crossmember is unbolted. No more lifting!

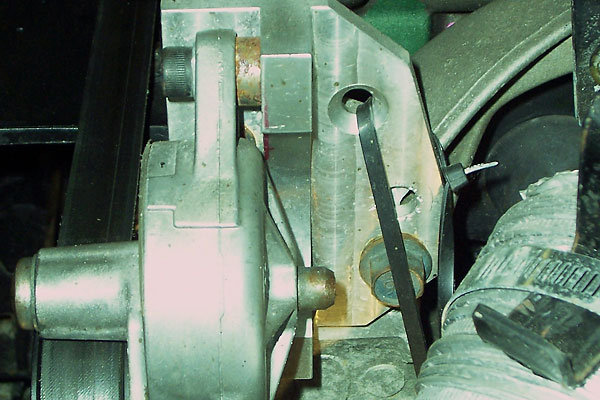

Caterham rubber motor mounts were used along with a custom steel bracket

which attaches through the center of the serpentine belt.

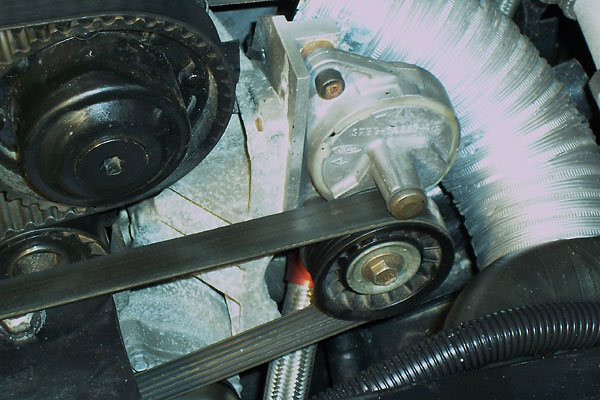

To keep the serpentine belt rotating correctly, an idler pulley and billet

bracket were purchased from Caterham. A Caterham radiator was also used.

A miniature single wire alternator was attached using fabricated brackets.

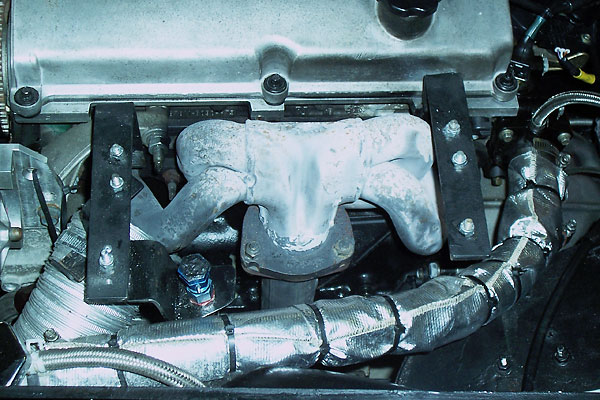

There's little room between the engine block and the steering shaft, so I

used a Ford Focus exhaust header. The four tubes sweep upward and then join into

a collector allowing sufficient space. I used 1 7/8 pipe for the remaining

exhaust system. Because of the proximity of the header to the hood, I

used a stainless steel heat shield over the header and also installed an

aluminum multi-layer blanket to the underside of the fiberglass hood.

The most difficult part of the conversion was the engine management system.

For years I attempted to use the Ford ECU and harness. I considered every

option I could research. Eventually I purchased a complete Alpha Gold System

from Webcon UK (www.webcon.co.uk). This kit supplies absolutely everything

you'll need.

The main features are Webers modified for port fuel injection, ECU, and

entire engine harness. All of the numerous components are original equipment

quality and the entire kit was labeled and came with the best installation

manual I've ever seen.

Webcon UK does not have any US dealers although 57 of the above kits were

installed on Superformance S1's which were sold here. I spoke at length were

their sales and engineering director prior to my purchase. The stock motor

grows from 135 hp to 171 hp with this kit according to dyno tests. I did

some serious porting and polishing of the intake manifold and coupled with

my exhaust header 175 to 180 hp is probably a conservative estimate for

my engine's performance. This is a costly investment, but knowing what I know

now I wouldn't entertain any other course of action.

The Michigan climate provides weather extremes, but the modern electronic

fuel injection system can't be beat for starting, idling and running in all

conditions. I have all of the wonderful handling attributes of an H-Production

Sprite racecar with the engine performance of a very hot modern sports car.

180 HP divided into 1,450 pounds is a little over 8 pounds per horsepower.

A 4,000 pound car would require about 497 hp to run with my little Sprite.

I'm currently using the 3.72 ring and pinion which is a great street combination

with the T9 transmission. 60 mph can be reached without leaving second gear

(at 6,000 rpm). Top speed at 6,000 rpm is estimated at 133mph. At 6,600 rpm,

the car could be 146mph.

The stock Sprite speedometer only goes up to 100 mph. I destroyed mine in short

order, and subsequently fitted an MGB speedometer which registers to 120 mph.

At the completion of the project I achieved my major goal of keeping the weight

of the Sprite at 1,450 pounds and thus not diminishing the balance, steering

feedback, or road holding.

Knowing what I know today I would describe this conversion as quite "do-able"

for most garage freaks. The amount of cutting of the Sprite's bodyshell was

relatively minor. The final outcome greatly exceeds my initial expectations.

Boy, how 16 years can blow by!

How It Was Done

| Engine: | Ford "Zetec" 2.0L DOHC 4-valve-per-cylinder (1999 Mercury Cougar)

with Webcon "Alpha Gold" induction and engine management system

(PN: K20016 - ECU & port fuel injection).

Engine redlines at 6,000 rpm, Rev-limiter (in ECU) is set for 6,600 rpm.

45mm throttle bodies. Pico fuel injectors. Stock Ford camshafts.

(Note: the servo for variable exhaust timing has been disabled.)

Raceline (5.75 qt) low-profile, cast aluminum oil pan with windage tray.

Fram HP-1 remote oil filter with Aeroquip braided lines.

Lotus engine idler system and serpentine accessory drive belt.

High output one-wire mini alternator mounted on custom brackets. |

| Cooling: | Caterham "Super 7" radiator and electric fan. Spun aluminum coolant

overflow tank. |

| Exhaust: | modified Ford Focus header, stainless heat shield, and custom

(1 7/8") straight flow exhaust system. |

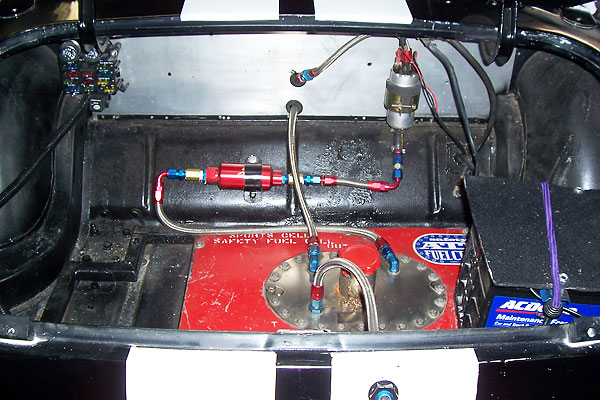

| Fuel system: | ATL Fuel Cell, filler foam, and anti-tip valve. Aeroquip fuel

lines including return circuit. Inertia switch for the fuel pump

is located in passenger's footwell. (Note: safety foam in the fuel

cell prevents use of a lever-arm fuel sensor, but it also dissipates

returned fuel. If the foam were removed, a swirl pot will be required.) |

| Transmission: | new Borg Warner (Ford) T9 5-speed transmission (as used in the Sierra

and Merkur, 1st:3.36, 2nd:1.81, 3rd:1.26, 4th:1.00, 5th:0.82, R:3.87.)

Lotus bell-housing. Annular (HTOB) clutch release (Ford PN: F5RZ-7A508-B).

Caterham lightweight flywheel, heavy duty clutch, & pressure plate.

Custom driveshaft (29.25" long) with safety hoop. Clutch master cylinder

has been re-sleeved in stainless steel. |

| Rear Axle: | stock axle with 3.72:1 gear and open differential in aluminum carrier.

(Current ratio will get car to 60mph in second gear. 4.22 and 4.55 gears

are kept in reserve.) High strength axle shafts. New bearings and seals. |

| Front Suspension: | reduced height racing coil springs. Adjustable bushings for setting camber.

(Currently running about 2 degrees of negative camber.) 7/8" roll bar. |

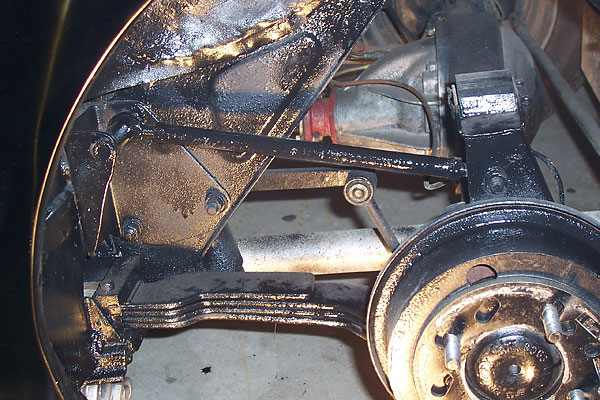

| Rear Suspension: | offset racing-spec leaf springs. Rose jointed radius arms. Custom Panhard bar. |

| Wheels/Tires: | Chevrolet Vega 13x5, 4-on-4", 0.20" offset, steel wheels with

BF Goodrich "Radial T/A" 205/50 tires. Oversized wheel studs

and 0.25" aluminum spacers. |

| Brakes: | (front) Sprite MkIII front disc brakes. (rear) stock drum brakes. Master cylinder has been re-sleeved in stainless steel. Aeroquip brake hoses. |

| Chassis: | main frame rails have been modified for increased width. A cowl hoop is hidden

under the instrument panel, with diagonal supports running forward from

it to the front subframe (all constructed from chrome-moly steel tubing.)

Custom front crossmember with Caterham motor mounts and revised steering

rack location. Custom transmission crossmember and modified tunnel. |

| Body: | fiberglass front and rear fenders with large flares. Mark I doors

(no window mechanisms). Reinforced fiberglass hood (mounted on pins.)

Original floor and trunk (no rust). Custom aluminum rear bulkhead.

Bumpers removed and bumper holes filled. All chrome trim removed.

Front valance with enlarged air intake. Chopped windshield (4.5").

PPG lacquer (no clear coat). White stripes (tape). |

| Interior: | fiberglass instrument panel with Stewart Warner gauges except for

a Smiths speedometer from an MGB (with 120mph top speed instead of

100mph). Cobra bucket seats with Simpson competition seat belts.

Race steering wheel with chest pad.

Custom armrest, carpet, and rubber mats. Aluminum floor trim.

Fire extinguisher. |

| Electrical: | ECU is located under the instrument panel on the passenger's side.

Painless wiring system (PN: 90501) installed with fuse panel in the trunk.

Trunk mounted battery. Battery tender. Exterior-mounted master cut-off switch. |

| Weight: | 1,450 pounds (wet) - approximately 8# per horsepower! |

| Performance: | approximately 175-180hp at the wheels. (Webcon dyno-tested the

engine before installation of the current exhaust header, and before

porting and polishing of the intake manifold. It was at 172hp in that

configuration.) |

| Completed: | June 2006. |

| Comments: | From 1977, this car was SCCA "H-Production" race car. (It was purchased

by Richard Bondy in June 1992.)

A modern multi-port fuel injection system with a custom programmed ECU is the only way to go if you want your Sprite to perform perfectly each and every day. It's wonderful never having to make excuses. This was my first Sprite conversion; the next one could actually be quite painless. Try it, you will like it! |

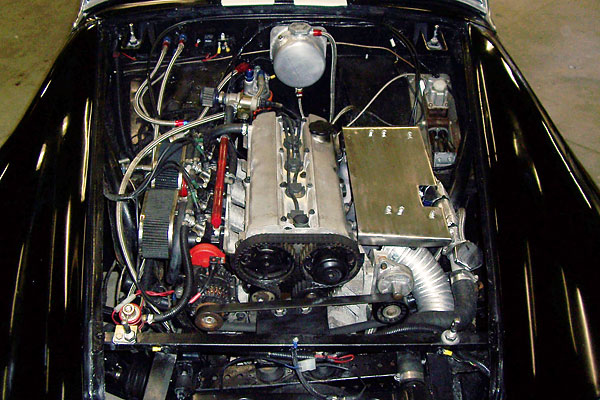

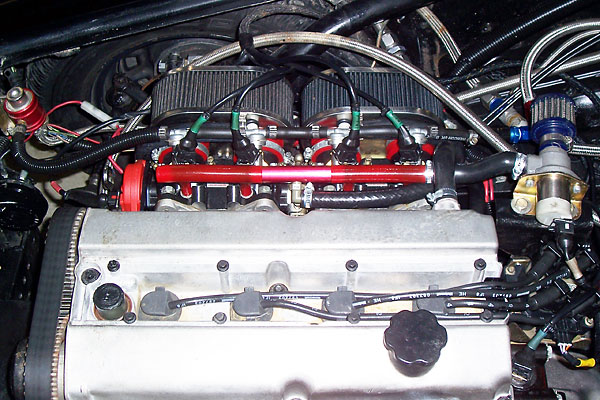

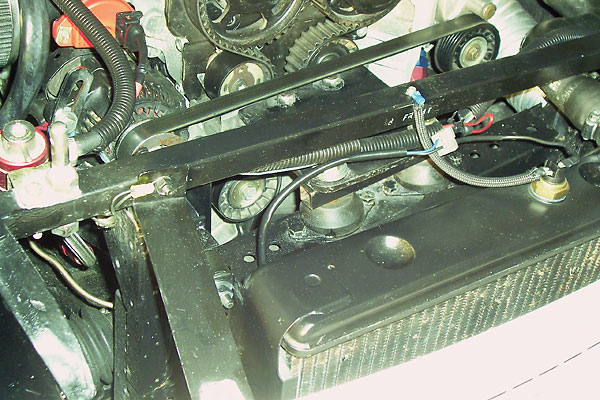

Engine Installation

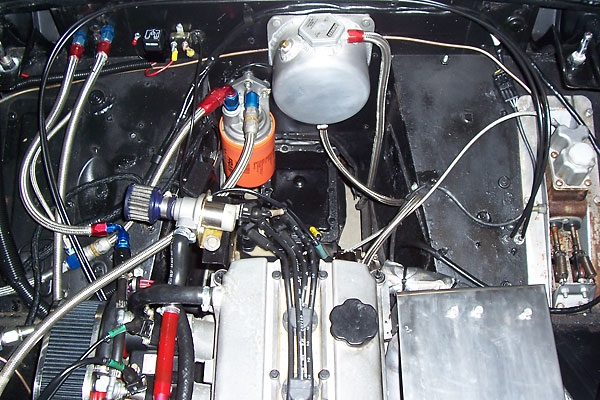

Ford Zetec 2.0L DOHC (1999 Mercury Cougar) with Webcon Alpha Gold induction/engine management.

Fram HP-1 remote oil filter with Aeroquip braided lines. Aluminum coolant tank.

Stainless steel exhaust heat shield.

Caterham Super-7 radiator and electric fan.

45mm throttle bodies. Pico fuel injectors.

High output one-wire mini alternator mounted on custom brackets.

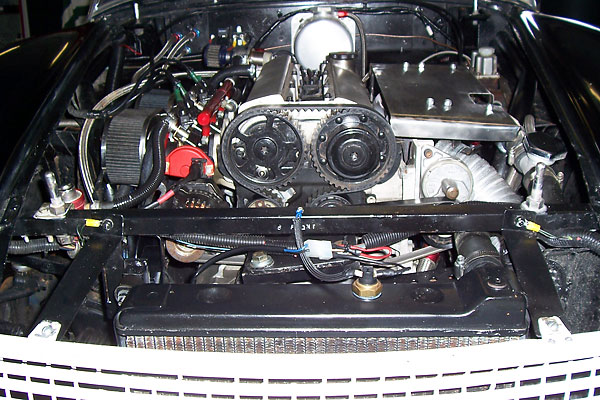

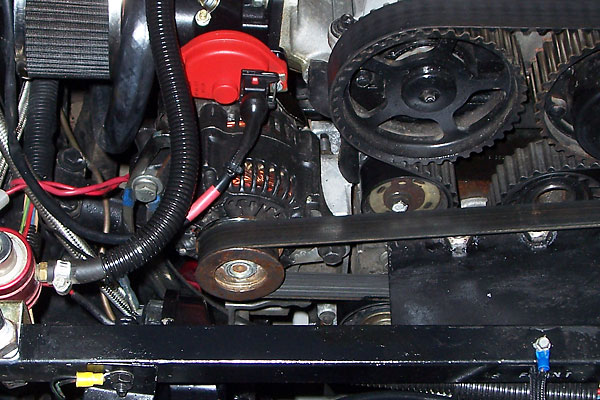

Lotus engine idler system and serpentine accessory drive belt.

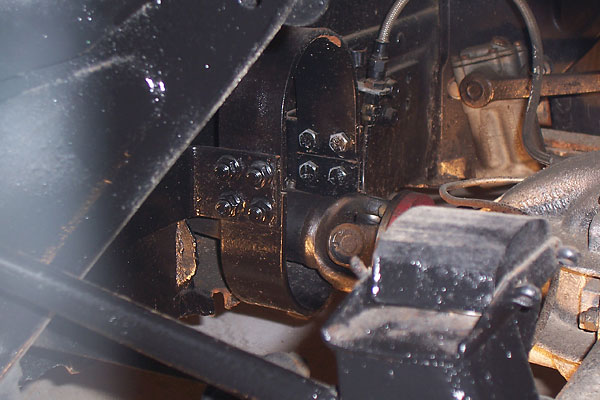

Side view of Lotus idler pulley.

Custom front crossmember with Caterham motor mounts.

Modified Ford Focus header.

ATL Fuel Cell, filler foam, and anti-tip valve.

Suspension Details

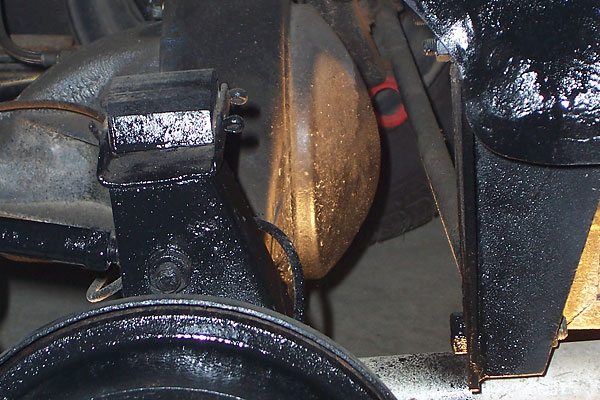

Offset racing-spec leaf springs and rose-jointed radius arms.

Custom driveshaft (29.25 inches long) with safety hoop.

Stock Sprite drum brakes, and custom 1-7/8 exhaust system.

Custom Panhard bar.

Chevrolet Vega 13x5 steel wheels with BF Goodrich Radial T/A 205/50 tires.

Enjoying this article? Our magazine is funded through the generous support of readers like you!

To contribute to our operating budget, please click here and follow the instructions.

(Suggested contribution is twenty bucks per year. Feel free to give more!)

Interior

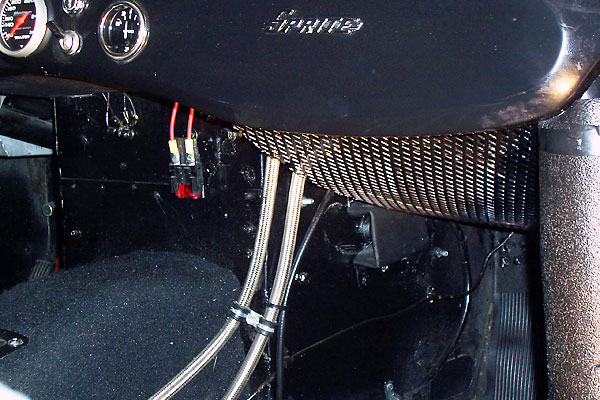

The cowl hoop from the old roll cage is hidden behind the instrument panel.

Cobra bucket seats with Simpson competition seat belts.

Stewart Warner gauges except Smiths MGB speedometer (120mph top instead of 100).

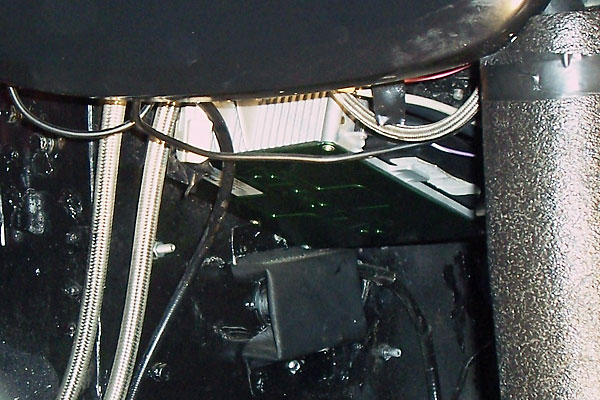

The engine ECU is located under the instrument panel on the passenger's side.

A screen protects the ECU and wiring.

Inertia switch for the fuel pump is located in passenger's footwell.

Exterior

Fiberglass hood, front fenders and valance (with enlarged air inlet and filled bumper holes.)

The windshield has been chopped 4.5 inches, and the top trim has been removed.

Fiberglass rear fenders with generously sized flares complete the racecar look.