�

�

�

Barry's Spitfire, with a EuroFord 2.8L V6

� (as recorded by Dan Masters)� �

�

The following is a copy of a post made to the Triumphs/Spitfires�

internet mailing list by Barry, and is reprinted here with his�

permission, along with some photos Barry provided especially for�

this web page.�

�

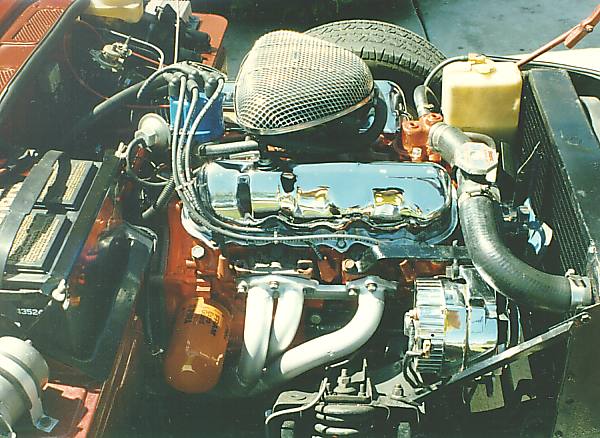

The engine (Ford 2.8) is almost stock except for a mild street cam and �

tube headers (required for installation). I had to modify the oil pan for�

frame clearance, which consisted of notching the front of the pan for the �

steering rack and angle notching the right side of the pan (for clearing �

the suspension mounting assembly). You must use the Capri rear sump pan �

and oil pump assembly. The EuroFord V6 was derived from a V4 with a �

balance shaft mounted in the right side of the block. When mounting the �

engine crankshaft centrally in the frame the engine will appear to be �

offset to the right. This is the extra material left over from the V4 �

balance shaft casting, the same basic casting with two extra cylinders �

added to make it a V6.�

�

�

�

�

�

Stock mounting locations were used on the frame but required new mounting �

brackets for the engine. GT6/TR6 engine mounts were used and cooling �

is handled through a custom-made, four tube, large, crossflow radiator with�

dual thermostatically controlled electric fans. This car never overheats, �

even in the hottest weather! The intake system is basically stock with a �

slight modification to the intake manifold. I milled approximately 1/2 inch �

off the carburetor mounting flange for under-hood clearance and removed the �

divider (to alter the two separate plenum chambers into one open plenum). �

A Weber 40 DFAV carb (siamesed opening of the throttles) feeds "regular" �

(87 octane) unleaded fuel to the engine. MOBIL-1 15-50 synthetic oil does �

the oiling job through a heavy-duty high capacity TRW oil pump.�

�

Modifications to the bellhousing consists of machining out the area where �

the starter mounts, welding in a new section for mounting of the 2600 CAPRI�

starter (smaller than the stock MUSTANG for frame clearance), and�

re-drilling/tapping for the starter mounting holes (it sounds worse than it �

actually was). I also moved the throwout bearing actuating arm from the left �

to the right side of the bellhousing (again, for clearance). The stock �

Mustang uses a cable operated clutch and I wanted to keep it hydraulic.�

�

�

�

�

�

�

Moving back to the transmission, gear ratios are stock MUSTANG V6 ratios, and �

seem perfectly suited for the car. The transmission is a Borg-Warner SR-4 �

MUSTANG V6 4 speed (the newer 5 speed would probably fit but I just haven't �

gotten around to finding out. I plan on installing one in the next couple of �

months [see footnote]). I used a Courier/Ford/Mazda clutch slave cylinder �

mounted on a fabricated bracket to the right side of the transmission. The �

only other modifications I made were to change the tailshaft extension. This�

was to bring the shift lever into the stock TRIUMPH mounting location. �

The extension used was from a 1978 AMC SPIRIT (GREMLIN). This along with the �

required main shaft was all that was needed. Unfortunately, this modification �

required making a new transmission yoke to match the rather smallish u-joints�

TRIUMPH uses.

�

�

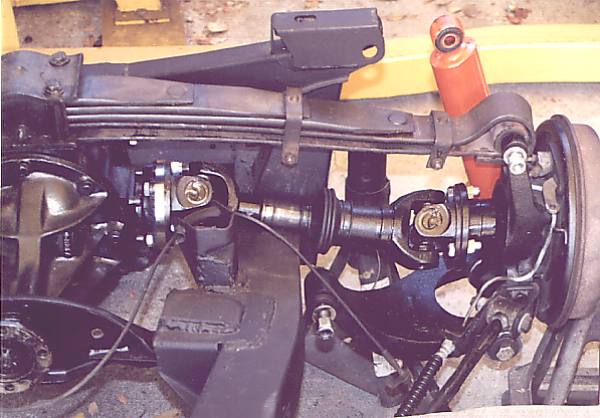

Mounting of the transmission was handled by manufacturing a new cross member�

using the 78' transmission mount. Shortening the drive shaft the required �

amount for the new installation we move on to the rear end! This is the �

weakest part of the drive train. I blew up three carriers until I finally got �

it right! I was using the stock SPITFIRE swing spring rear suspension, which �

is adequate if you use a carrier from a 76 or later Spitfire... but I just�

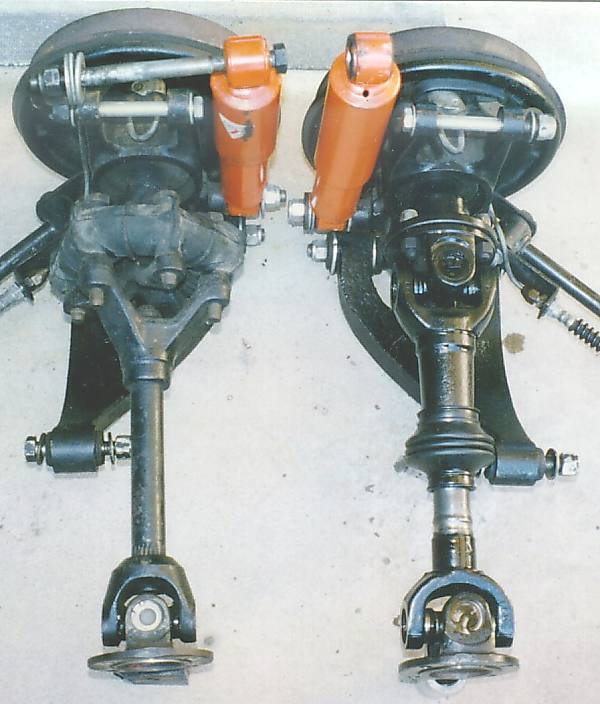

couldn't leave well enough alone! I decided to adapt the all-independent GT6+ �

rear suspension.

�

�

The modifications required were to make and weld new mounting brackets for the�

lower wishbones (now you can buy them), also to manufacture and weld the upper �

shock mounting brackets into the inner wheel well arches (you can buy these now �

as well). 1/4" spacers were required at the rear to clear the shocks (wider �

than stock tires) at the upper wheel locations hence the 49.50" rear track. I�

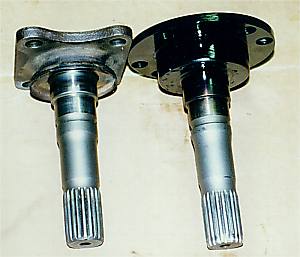

also replaced the rotoflex joints and axles with TR6 sliding axle shafts by �

re-manufacturing the hubs and differential mounting flanges to accept the �

bigger (stronger) TR6 U-joints with axles. I got real tired of replacing the �

rotoflex couplings about every three months! Apparently the torque of the �

little V6 was just too much for the rubber u-joints! �

�

�

�

�

�

As this car is constantly evolving I also just completed installing a Quaife �

torque sensing diff. I had to replace the 3:27 gears with 3:63 because the �

Quaife wouldn't accept the 3:27's. With the lower ratio I really could use the �

5 speed's overdrive!

�

�

�

Footnote:

�

I have installed the T5, but that's a whole 'nother page. LOTS of work, involving �

some frame trimming, tunnel fabrication, mod's, machining etc. but well worth it �

for this engine and this rear-end ratio!�

�