Christopher Trace's 1974.5 TR6 is Powered by a Ford 302 V8

as published in British V8 Newsletter, Volume XI Issue 3, September 2003

Owner: ChristopherTrace

City: Beeton, Ontario, Canada

E-mail: catrace @ rogers.com

Model: 1974.5 Triumph TR6

Engine: Ford 302

Conversion performed by: Owner

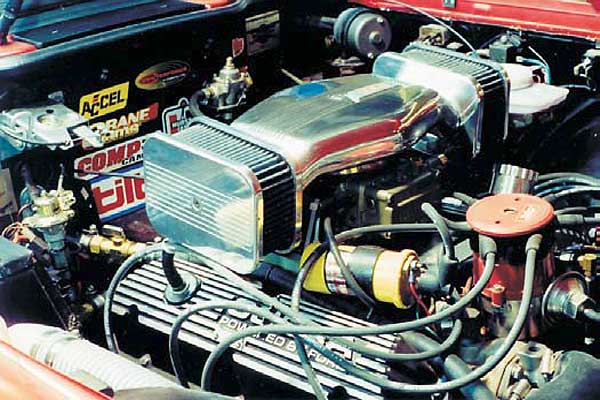

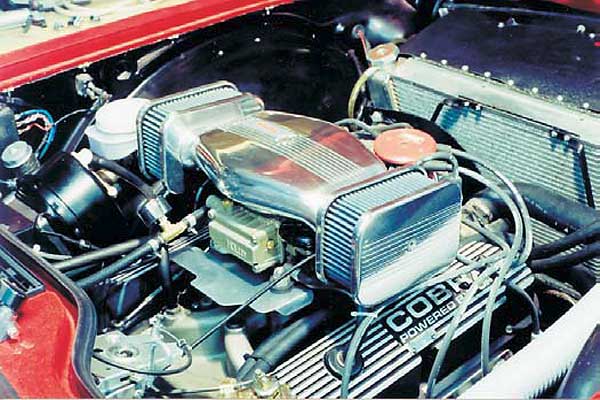

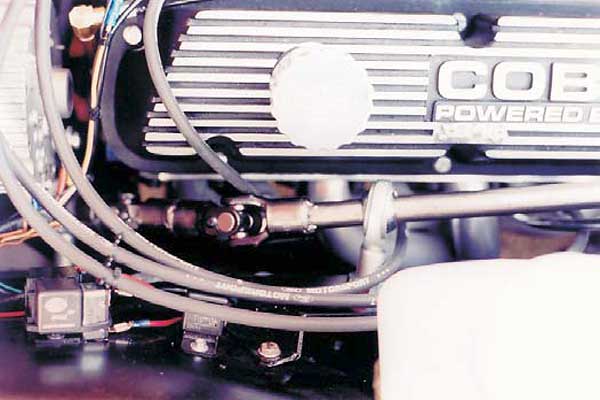

| Engine: | Ford 302 bored out to 310ci, and completely rebuilt. Aluminum high-compression pistons

are used with 1/16th" chrome-moly rings. A mild Crane cam (towing grind) is used. A heavy

duty oil pump and shaft helps to prolong engine life. |

| Intake: | A Holley 600cfm 4 barrel carburetor sits on an Edlebrock Torquer II manifold, and breathes

through a side draft air cleaner. A heat shield is slipped between the carburetor and the manifold. |

| Engine Electrical: | An Accel distributor feeds an electronic ignition system and a high output coil. |

| Drivetrain: | Transmission is a BW T5 World Class 5-speed with a Hurst shifter. A Centerforce

dual-friction clutch is actuated by a Tilton hydraulic throw-out bearing. Power is sent

to the rear by way of a custom made 21/2" drive shaft. |

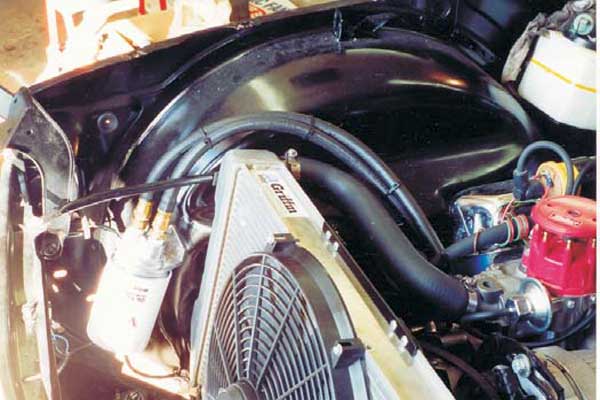

| Cooling: | A Stewart Stage 1 water pump circulates coolant through a Griffin cross-flow radiator,

where it is cooled by a 16" electric cooling fan in a "pusher" configuration. A fan shroud

is provided to ensure all the air flows through the radiator instead of around it. |

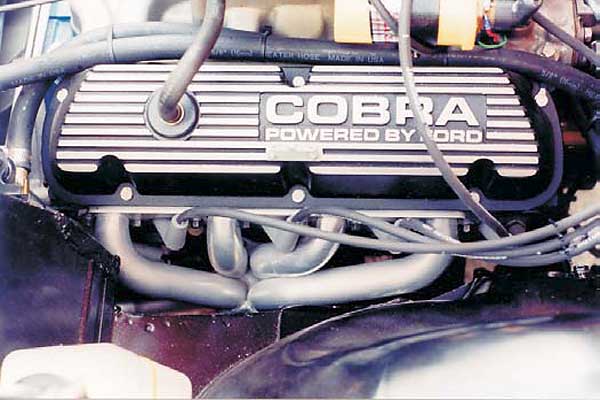

| Exhaust: | Sanderson street rod headers, ceramic coated, send the spent gases through a custom

made stainless steel exhaust system. |

| Rear axle: | The stock IRS differential is retained, but it has been rebuilt, as have the rear hub

assemblies, with new U-joints all around. The differential is now suspended with

polyurethane bushings. The differential mounting brackets have been reinforced. |

| Front Suspension: | KYB shocks are used, along with new springs and polyurethane bushings. A new sway

bar was fitted. |

| Rear Suspension: | Lever action shocks have been replaced with a tube shock conversion. New springs

and polyurethane bushings are used, along with a rear sway bar. |

| Brakes: | A complete new brake system has been installed - M/C, wheel cylinders, brake lines,

pads, discs, and drums - and braided stainless steel lines are used for the flex-lines.

Toyota 4-pot calipers are used in front, and 7/8" Sunbeam Alpine rear wheel cylinders

are used. Brake fluid is Silicon DOT5. |

| Wheels/Tires: | Pirelli P6000 Sport Veloce 215/65/R15 tires are fitted to 15X6 Panasport aluminum wheels. |

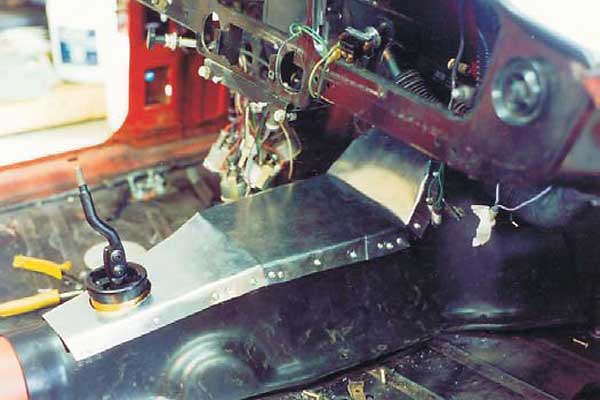

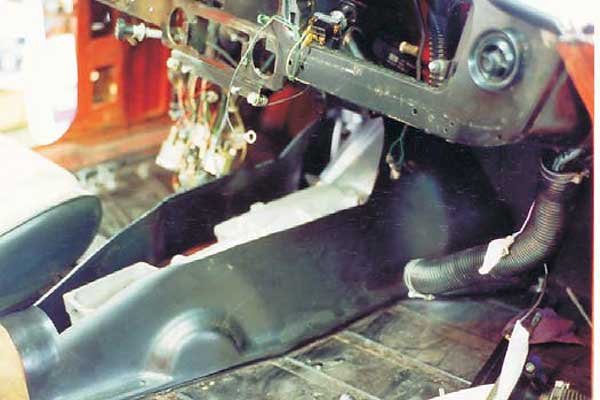

| Interior: | Seat rebuilt with new foam, diaphragms, and leather seat covers. New carpets installed,

with double underlay and heat shield. Dash has been re-veneered and an Alpine stereo system

added. For comfort, fresh air ducts vent cool air to the footwells. The old top has been

replaced with new. |

| Body/Paint: | Six coats of Sikkens "Rio Red" acrylic urethane paint. |

| Electrical: | GM alternator replaces the anemic Lucas unit. All wiring bullets have been replaced.

Headlamps are now Halogen. |

| Fasteners: | All load bearing points have grade 8 fasteners. All other points are stainless steel. |