Jim Prettyleaf's 1971 Triumph TR-6 with Buick 231 V6

as published in BritishV8 Magazine, Volume XVI Issue 2, October 2008

Owners: Jim Prettyleaf

City: Cupertino, CA

Model: 1971 Triumph TR-6

Engine: Buick 231 V6

Conversion performed by: owner

| Engine: | 1984 Buick 231cid (3.8L) V6 with 10:1 compression. Edelbrock Performer

intake manifold. Holley 390cfm four barrel carburetor. MSD ball bearing

distributor with MSD 6AL spark box. Kenne Bell "Mark 2X" camshaft

(intake: 0.478" lift / 270 duration, exhaust: 0.494" lift / 280 duration.)

Roller rockers (1.6:1). |

| Exhaust: | custom 3-into-1 headers fabricated by San Francisco Muffler. |

| Cooling: | custom radiator, built using stock TR-6 top and bottom tanks with

enlarged inlets/outlets and a 3-row replacement core. Electric (pusher) fan. |

| Transmission: | Muncie M21 4-speed, with 1:1 top gear. Lightweight billet steel flywheel

with 10.4" Centerforce clutch and hydraulic throw-out bearing. Custom

driveshaft and halfshafts fabricated by San Jose Drive Line. |

| Rear axle: | Chevrolet Corvette C3 differential with limited slip differential and

3:54:1 final drive ratio. |

| Suspension: | (front) modified TR-6 with 6 degrees of castor and 3 degress

of negative camber, utilizing "Uncle Jack Drews" spindles.

(rear) Custom 3-link independent rear suspension with bespoke halfshafts

and Summers Brothers stub axles. |

| Chassis: | added triangulation at the front and rear of the TR-6 frame, plus

chassis brace with integrated roll bar. The body is mounted solidly

to the frame with aluminum spacers to provide additional longitudinal

bracing. |

| Brakes: | high coefficient rear brake linings with 0.87" diameter rear wheel

cylinders from Sunbeam Alpine/Tiger and Wilwood brake bias valve to

adjust front-to-rear balance. |

| Wheels/Tires: | Carroll Shelby 15x8.5 8-spoke wheels. Hoosier A6 225/45ZR15 autocross tires. |

| Weight: | 2426 pounds. |

| Interior: | Auto Meter Sport Comp "Monster" tachometer with stock 1971 TR-6 white on

black gauges. |

| Comments: | this car has been rebuilt three times now. The first version used an

odd-fire 225cid Buick V6 - it was completed in 1977; This third version,

featuring the even-fire 231cid V6 was completed in 2003 and has been driven

about 6000 miles as of June 2008. This car isn't as quick in a straight

line as some of the V8 conversions, but it turns and sticks hard enough to

induce nose bleeds! |

Normally aspirated Buick 3.8L V6 with 10.1:1 compression...

TR-6 frames are much too flexible, and the stock independent rear suspension

has weak stub axles that can be broken by souped up versions of the original

2.5 Liter inline six. Dead stock 2.5 Liter engines routinely break the right

front and the left rear frame mounts for the stock differential. When swapping

to a different engine that supplies more power and torque the stock independent

suspension will require substantial upgrades and the differential mounts must

be reinforced. The other option is to convert the car to a much stronger live

axle, but this is also problematical since modern autocross tires provide more

grip with negative camber set somewhere in the -2 to -3 degree range.

To put more power in the TR-6 the stiffness of the chassis should be

substantially improved or torque steer will quickly become objectionable.

Revision one of my Buick V6 powered car made about 160 horsepower but with

no chassis stiffener the car wanted to jump to the right about half of a

lane when shifting from first to second at full power. The revision three

car uses a nicely hotted up 231 cubic inch (3.8L) engine that is pumping

out about 300 horsepower at the crank but the chassis stiffener keeps the

car moving straight ahead during every upshift.

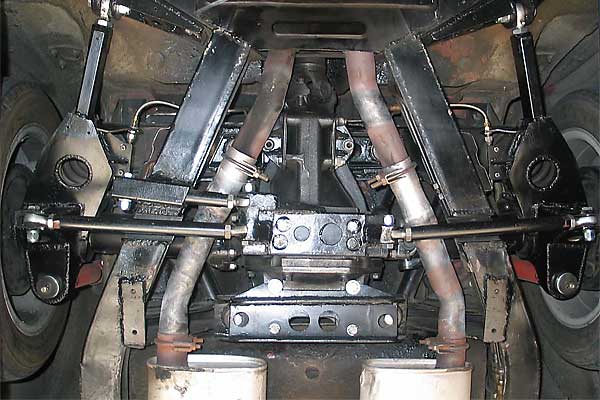

The custom made half shafts and the Summers Brothers stub axles are

strong enough to transmit 400+ horsepower. The Corvette differential is

mounted to lightweight cellular steel mounts that can stand up the driveline

torque and the rear wheel reaction torque in low gear. The front and rear

cross members for the differential mountings are connected by triangulated

steel tubes that are welded in place to transfer forces directly into the

remainder of the chassis stiffener and roll bar assembly. The differential

is attached to the cross members by four captive rubber mounts that were

also burrowed from the C3 Corvette.

Enjoying this article? Our magazine is funded through the generous support of readers like you!

To contribute to our operating budget, please click here and follow the instructions.

(Suggested contribution is twenty bucks per year. Feel free to give more!)

The homemade independent rear suspension (IRS) has a single leading

link that connects to the TR-6 chassis via a spherical bearing tie rod end.

The thrust loads from the spherical bearing are distributed to the four

mounting holes for the stock semi-trailing arm by a lightweight triangulated

bracket. The back end of the trailing arm has a mounting flange that mates

to the original TR-6 rear wheel bearing carriers. The half shafts have no

slip-splines, so the upper transverse link of the short-long-arm IRS is

the rotating half shaft. This is the same rear suspension scheme as used

by the C3 Corvette so the differential bearings and housing were designed

to cope with the lateral suspension loads. The lower transverse link of

the short-long-arm suspension is a structural steel tube with left-hand and

right-handed threads and spherical rod ends. The longer lower link connects

to a short lightweight triangulated arm that projects downward from the

mounting flange for the bearing carrier / leading link assembly. The leading

link / rear suspension upright assembly is a mild steel weldment with a

finished weight that is less than the original Triumph aluminum alloy

semi-trailing arm. The steel mount that attaches the lower transverse

links to the case of the Corvette differential also provides an attachment

point for a Panhard rod that connects to the right hand frame rail of the

TR-6 frame. Rear wheel reaction torque and driveshaft reaction torques are

absorbed by the four rubber mounts at the top of the differential, but the

lateral motion of the differential is tightly constrained by the panhard rod

so that the rear suspension geometry remains very stable when lateral loads

are applied in the turns.

When the revision three car is driven into a turn too fast and the driver

feathers off the power the homemade three and one half link IRS gathers up

much quicker than the original Triumph semi-trailing arm IRS. The homemade

IRS also has less camber change from bump to rebound than the stock semi-trailing

arm suspension, so the car is much more tolerant of uneven pavement and

applications of engine torque.

The generation three Triuick is a blast to drive! The Buick V6 is a very

light relatively large swept volume engine, without the driver this car has a

measured weight distribution of 48% front 52% rear. This car provides the best

tactile feedback to the driver's fingertips of anything I have ever driven and

that is saying something since I started driving sprint go-karts before I was

old enough to have my first driver's license. I am still fine tuning the

chassis settings but a recent change that reduced the rear camber from -2.5

degrees to -2.0 degrees gave an impressive improvement in the rear grip.

Holley 390cfm four barrel carburetor on an Edelbrock Performer manifold.

Tall valve covers are needed to clear roller rockers and high cam lift. (The car doesn't have a turbo.)

Headers, trap-door oil pan, and Muncie M21 close-ratio four speed transmission.

The chassis stiffener and roll hoop weigh 45 pounds total.

Integration of chassis stiffener and TR-6 chassis.

Beefed up differential mounts and rear crossmember braces.

New three-link independent rear suspension.

Comparing the Summers Brothers stub axle (left) with the old TR-6 stub axle and flange (top right and center).